well in most arguments there are 3 sides.... their side, our side, and the TRUTH

i dont care for "wives tales" and i dont care to make cool noise when i let out of the throttle.

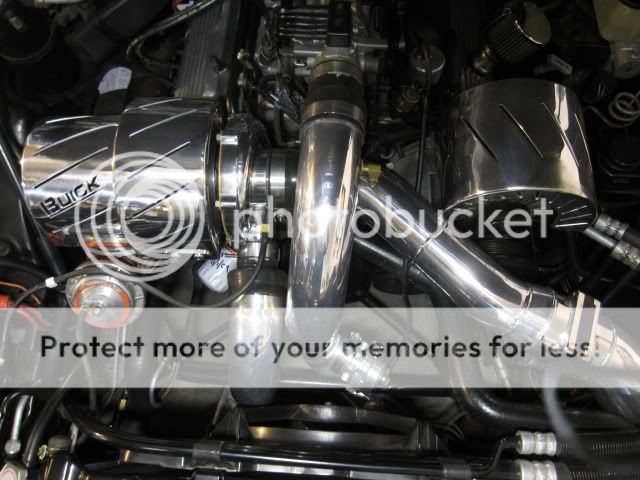

I DO CARE about the longevity of my turbo and assicociated parts. that being said when thought about for a bit, the BOV becomes a necessary part of any turbo system. most buick guys will tell you that the BOV doesnt make the car go any faster which is true, in fact if set up wrong, the BOV will only slow a tubo car down. the secret is to set it up correct as to not bleed out boost while under WOT and to fully evacuate excess pressure when the throttle "snaps" shut

currently on the auto industry, every auto manufacturer on planet earth that produces a turbo car has a BOV built into the turbo system (auto or manual), also known as a recirculation valve. if every major auto corporation puts cash into installing a recirculation valve (BOV),than shouldnt we? im talking about companys that wont waste a dime on anything that wont improve the product at hand either in mpg, value, performance, saftey, or reliability.......

stock car manufacturers install BOV's for a reason, 99% of outlaw 10.5 racers install BOV's for a reason, and so will I

What about the millions of turbo diesel trucks out there? Do they have a BOV?