You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dynamic EFI EBL Flash System For GM Sequential V6 Boosted Engines....

- Thread starter Street Lethal

- Start date

Street Lethal

Tech Anarchist

- Joined

- Oct 8, 2006

Wish I could see the vid! I am working on getting the the work done on the body so I can get it back on the finished chassis. No EBL progress yet.

Which video, the one I posted? Believe it or not there was an error code for the knock sensor still prevalent during that video, now with the knock sensor temporarily disabled in the EBL, the damn engine feels like it wants to pull the car through a brick wall. Have to be careful though, at least until I get a new knock sensor back in there, just not in a rush to drain the engine coolant so I'm stalling with the install...

- Joined

- Aug 1, 2003

on lc2 the knock sensors arent installed into coolant , they are in the bellhousing area

if your 305 has it in the coolant just swap it out quick , use your finger to cover hole and there shouldnt be much coolant loss, make sure the cap is on radiator and that will slow down coolant loss during the swap, put the cap in a plastic bag and screw it back on and the cap will not vent back

if your 305 has it in the coolant just swap it out quick , use your finger to cover hole and there shouldnt be much coolant loss, make sure the cap is on radiator and that will slow down coolant loss during the swap, put the cap in a plastic bag and screw it back on and the cap will not vent back

Last edited:

Street Lethal

Tech Anarchist

- Joined

- Oct 8, 2006

on lc2 the knock sensors arent installed into coolant , they are in the bellhousing area

if your 305 has it in the coolant just swap it out quick , use your finger to cover hole and there shouldnt be much coolant loss, make sure the cap is on radiator and that will slow down coolant loss during the swap, put the cap in a plastic bag and screw it back on and the cap will not vent back

Yes definitely, it is at the bottom of the block, and also used as a coolant drain. Misplaced my digital volt meter, but hopefully the clerk at Advanced Auto has one there to check the resistance of the KS for me before I leave with it. I cut the intermediate pipe off yesterday, and pulled off the Flowmaster muffler. I now have four catalytic converters that I am doing nothing with, and was told I could get $100.00 for each of them from some place in NJ? I have a low mileage 3" Catco Converter (universal) Paul, let me know if you could use it...

Finally installed the new KS on my car, took apart the old one for sh!ts and giggles. Before I took it apart I could shake it and hear something rattling around in there, once apart found the resistor broke off the piezo and grounding tab. Still have knock in the same rpm range (3600-4000) but not as much, car doesnt nose over nearly as bad. 15psi, timing is pulled back a few degrees, AFR around 11:1. I need to fab up another exhaust hanger for the cat delete pipe, Im thinking the DP is touching the pinch weld on the firewall, or excessive transmission noise may be a contributer. I hear no audible knock, exhaust is quiet enough and I roll the windows up for a WOT blast, lifters are a little loud for my liking once warm, but I guess thats normal. If I need to de-sensitize the KS, what would be a good source for a bushing? Black pipe iron female adapter from the HD or Lowes? Or a brass fitting?

RmvBfrFlght

Well-Known Member

- Joined

- Sep 28, 2007

Finally installed the new KS on my car, took apart the old one for sh!ts and giggles. Before I took it apart I could shake it and hear something rattling around in there, once apart found the resistor broke off the piezo and grounding tab. Still have knock in the same rpm range (3600-4000) but not as much, car doesnt nose over nearly as bad. 15psi, timing is pulled back a few degrees, AFR around 11:1. I need to fab up another exhaust hanger for the cat delete pipe, Im thinking the DP is touching the pinch weld on the firewall, or excessive transmission noise may be a contributer. I hear no audible knock, exhaust is quiet enough and I roll the windows up for a WOT blast, lifters are a little loud for my liking once warm, but I guess thats normal. If I need to de-sensitize the KS, what would be a good source for a bushing? Black pipe iron female adapter from the HD or Lowes? Or a brass fitting?

A short piece of iron pipe and a coupler works. I did the same thing as there was random false knock. But the worse was when the shifter was pulled back to 2nd gear. The increased line pressure made enough noise (pump likely) that there was continuous knock being reported. Can't get up and go with timing being pulled for no reason.

RemoveBeforeFlight

RmvBfrFlght

Well-Known Member

- Joined

- Sep 28, 2007

Is a flex fuel add-on something you'll have in the future?

It isn't in the plans at this time. Have the flex-fuel sensors come down in price at all? That is the main reason we haven't done anything along these lines.

If the E content is consistent it is easy enough to tune/calibrate the ECM for ethanol base fuels.

RemoveBeforeFlight

I've got ~$125 in my sensor, wiring harness, and -6 couplers.It isn't in the plans at this time. Have the flex-fuel sensors come down in price at all? That is the main reason we haven't done anything along these lines.

If the E content is consistent it is easy enough to tune/calibrate the ECM for ethanol base fuels.

RemoveBeforeFlight

Street Lethal

Tech Anarchist

- Joined

- Oct 8, 2006

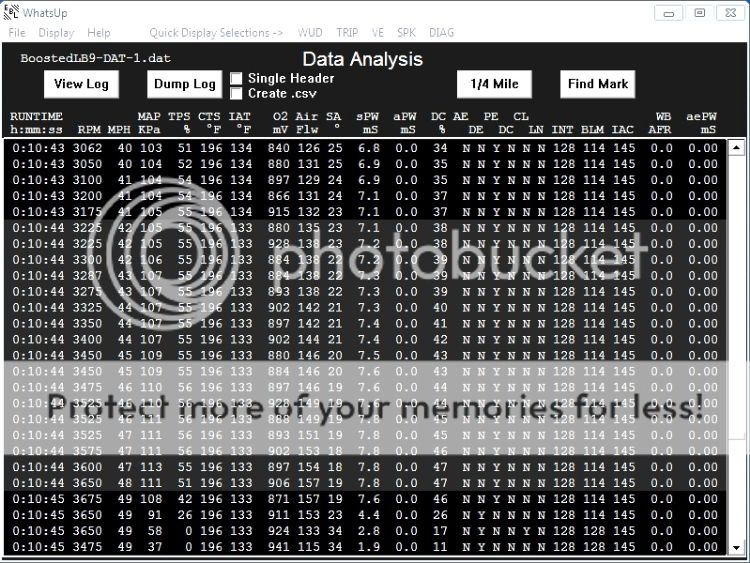

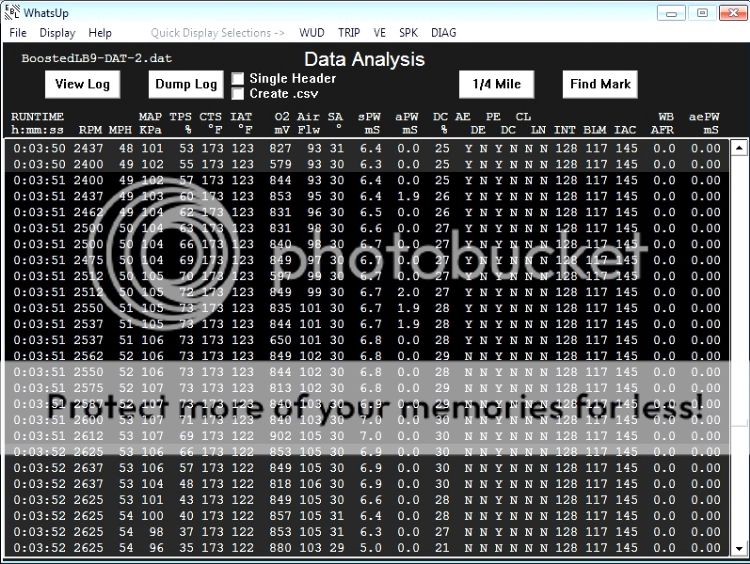

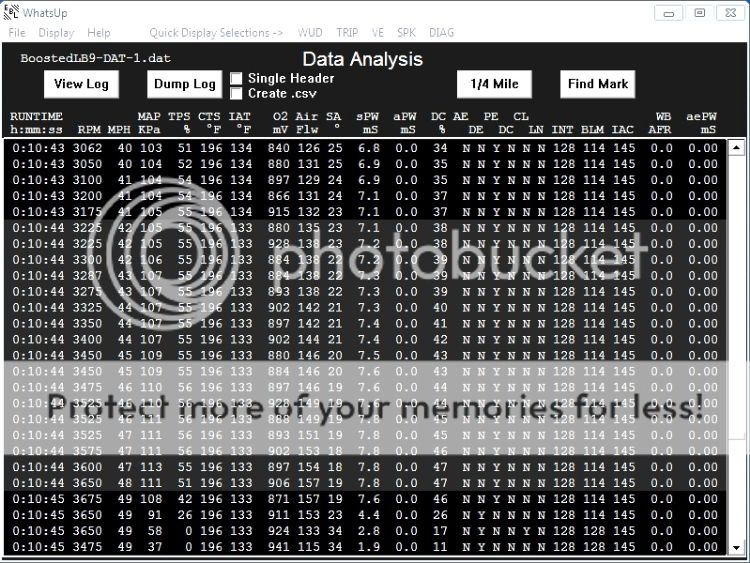

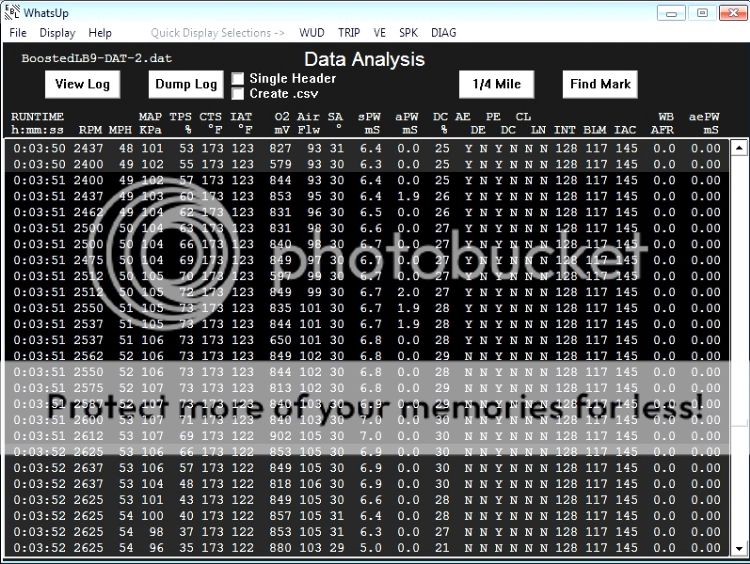

Just been data-logging a little, nothing tremendous. IAT's are high because the engine was idling for awhile before being restarted for this log. Just dialing in the fuel little by little up to 15-psi again, got a ways to go. First log shows the spark advance being off about 10 degrees, which was my fault, had the wrong setting in the 100-KPa cells in the main table. Second log shows it being fixed a few minutes later. 90 degrees today, too hot for this freaking stuff...

Street Lethal

Tech Anarchist

- Joined

- Oct 8, 2006

I gotta get another O2 bung and put it next to the NB sensor bung you welded in for me, then run that Innovative heat sink housing adapter with the WB, especially now because the exhaust is completely off, just the downpipe is on there again. I'm also nervous to pull fuel with the IAT's that high, as once they lower down it should lean out some. When I open the throttle by hand all the way, I get 89% TPS. In the log above, PE is active at 37% TPS and shuts down at 35% TPS. That is more than likely because of the stock 305-TPI bin I started with, being that RPM was so limited with TPI engines from the factory. How do I raise/lower that setting in Tuner Pro, and what would be a good PE setting for the TPS% to kick in with running a 6200-RPM limit...?

Edit: Duh, I found it after reviewing Bob's instructions in my build thread...

PE - TPS% Enable Threshold

Current setting is;

RPM - TPS%

0800 - 40.00

1600 - 40.00

2400 - 46.27

3200 - 50.20

4000 - 60.39

4800 - 60.39

5600 - 60.39

6375 - 60.39

So I am setting/targeting for the PE to activate just before boost comes in? Should I average out those values when I have all four individual values for each gear that I am in first, because they vary?

... also note;

PE - TPS% Hyst is set to 10.98%, which of course needs to be changed too?

Edit: Duh, I found it after reviewing Bob's instructions in my build thread...

PE - TPS% Enable Threshold

Current setting is;

RPM - TPS%

0800 - 40.00

1600 - 40.00

2400 - 46.27

3200 - 50.20

4000 - 60.39

4800 - 60.39

5600 - 60.39

6375 - 60.39

So I am setting/targeting for the PE to activate just before boost comes in? Should I average out those values when I have all four individual values for each gear that I am in first, because they vary?

... also note;

PE - TPS% Hyst is set to 10.98%, which of course needs to be changed too?

Last edited:

RmvBfrFlght

Well-Known Member

- Joined

- Sep 28, 2007

Need to get the VE tables closer. Can't really tune in the boost with a BLM of 114 - 117, those values will be ignored in PE mode and 128 used.

> When I open the throttle by hand all the way, I get 89% TPS.

The TPS gain can be adjusted in the calibration:

TPS - ADC Gain Term for TPS%

That entry is right after the "SA - " entries.

> So I am setting/targeting for the PE to activate just before boost comes in?

Should be in PE mode by 70 - 80 KPa or so. As you mentioned, see what TPS% gets you there and adjust accordingly. This is one item we fixed in the EBL SFI-6 firmware. There is also a PE mode versus MAP KPa table. So either TPS% or MAP can be used to enable PE mode.

RemoveBeforeFlight

> When I open the throttle by hand all the way, I get 89% TPS.

The TPS gain can be adjusted in the calibration:

TPS - ADC Gain Term for TPS%

That entry is right after the "SA - " entries.

> So I am setting/targeting for the PE to activate just before boost comes in?

Should be in PE mode by 70 - 80 KPa or so. As you mentioned, see what TPS% gets you there and adjust accordingly. This is one item we fixed in the EBL SFI-6 firmware. There is also a PE mode versus MAP KPa table. So either TPS% or MAP can be used to enable PE mode.

RemoveBeforeFlight

Street Lethal

Tech Anarchist

- Joined

- Oct 8, 2006

Need to get the VE tables closer. Can't really tune in the boost with a BLM of 114 - 117, those values will be ignored in PE mode and 128 used.

The boost tables work with the final value in the 100-KPa cells for their pulse width multipler calculation, correct? So then we should just ignore the BLM value in the datalog during PE because that value just locks at that moment, and long term fuel trim resumes where it left off in the BLM when Closed Loop re-enables, correct? So the best bet would be; force wastegate open, complete naturally aspirated VE tune, then resume from there?

The TPS gain can be adjusted in the calibration:

TPS - ADC Gain Term for TPS%

That entry is right after the "SA - " entries

Should be in PE mode by 70 - 80 KPa or so. As you mentioned, see what TPS% gets you there and adjust accordingly. This is one item we fixed in the EBL SFI-6 firmware. There is also a PE mode versus MAP KPa table. So either TPS% or MAP can be used to enable PE mode.

Okay Bob, that percentage is already set to 96.00 Gain in the bin, am I increasing it to 107.00 since I am reading 89% at full open throttle to make it read 100%? I am going to go out now and datalog each gear to see when boost comes in, then average out a decent PE trigger setting collectively...

RmvBfrFlght

Well-Known Member

- Joined

- Sep 28, 2007

The boost tables work with the final value in the 100-KPa cells for their pulse width multipler calculation, correct?

Yes.

So then we should just ignore the BLM value in the datalog during PE because that value just locks at that moment, and long term fuel trim resumes where it left off in the BLM when Closed Loop re-enables, correct?

Can't ignore the BLM in PE mode. If the BLM is 128 or greater it will be used to trim the fuel in PE mode. But it will not be used in PE mode if less then 128. So with a BLM of 114 - 117, and not being used in PE mode, will make PE mode that much richer.

Of course this also depends upon how closely the VE tables track. IOW, as the RPM increases, if the real VE increases above what is in the VE table, then it will go leaner as the RPM increases.

So the best bet would be; force wastegate open, complete naturally aspirated VE tune, then resume from there?

Yes, get the VE tables as close as possible before tuning boost. With an internal WG I just disconnected the rod from the puck arm.

Okay Bob, that percentage is already set to 96.00 Gain in the bin, am I increasing it to 107.00 since I am reading 89% at full open throttle to make it read 100%? I am going to go out now and datalog each gear to see when boost comes in, then average out a decent PE trigger setting collectively...

Getting the TPS% gain right is easy to do with the engine off. Tweak the gain term, flash it in, and see how much closer to 100% WOT is. Rinse and repeat.

RemoveBeforeFlight

Street Lethal

Tech Anarchist

- Joined

- Oct 8, 2006

Here are the 1st, 2nd and 3rd gear datalog results for when the engine actually see's boost...;

(note this is before I changed TPS% Gain)

1st Gear; 4000-RPM @ 71% TPS

2nd Gear; 3900-RPM @ 70% TPS

3rd Gear; 2400-RPM @ 65% TPS

... just gotta love that 700R4 w/3.42 combo.

I will set the TPS% Gain right now to embellish 100% at wide open throttle...

(note this is before I changed TPS% Gain)

1st Gear; 4000-RPM @ 71% TPS

2nd Gear; 3900-RPM @ 70% TPS

3rd Gear; 2400-RPM @ 65% TPS

... just gotta love that 700R4 w/3.42 combo.

I will set the TPS% Gain right now to embellish 100% at wide open throttle...

Street Lethal

Tech Anarchist

- Joined

- Oct 8, 2006

You were right, setting the TPS% Gain was super easy, it was harder getting in and out of the car lol. I was close with my guess, as 107.00 brought me to 99% TPS, but 108.00 got me right at 100% TPS...

Now I have to figure out the best PE TPS% thresholds to go with...

If I don't change the MAP TPS% thresholds, will the two play tug of war, or compromise and average it out?

Now I have to figure out the best PE TPS% thresholds to go with...

If I don't change the MAP TPS% thresholds, will the two play tug of war, or compromise and average it out?

Street Lethal

Tech Anarchist

- Joined

- Oct 8, 2006

Here are the 1st, 2nd and 3rd gear datalog results for when the engine actually see's boost...;

1st Gear; 4000-RPM @ 71% TPS

2nd Gear; 3900-RPM @ 70% TPS

3rd Gear; 2400-RPM @ 65% TPS

After adjusting the TPS% Gain to read 100% at WOT by adding 12 to the stock bin value in that location, I then added 12 to the numbers above that I got during the datalogging, and am averaging about 80% TPS from 2400-RPM to 4000-RPM. So, what do you guys think about these new TPS% threshold values;

Current setting is;

RPM - TPS%

0800 - 40.00

1600 - 40.00

2400 - 46.27

3200 - 50.20

4000 - 60.39

4800 - 60.39

5600 - 60.39

6375 - 60.39

New settings are;

RPM - TPS%

0800 - 52.00

1600 - 52.00

2400 - 76.00

3200 - 79.00

4000 - 82.00

4800 - 83.39

5600 - 83.39

6375 - 83.39

Do you agree...?

RmvBfrFlght

Well-Known Member

- Joined

- Sep 28, 2007

Retain the original settings, want to be in PE mode before boost arrives.

Also, on the TPS% gain, double check it via the go-pedal, it should also reach 100%. If not then there is either a floor mat under the pedal or the throttle cable has stretched.

RemoveBeforeFlight

Also, on the TPS% gain, double check it via the go-pedal, it should also reach 100%. If not then there is either a floor mat under the pedal or the throttle cable has stretched.

RemoveBeforeFlight

Street Lethal

Tech Anarchist

- Joined

- Oct 8, 2006

Okay, I put the original settings back. Just checked the pedal, matches 100% TPS....

Don't wanna wait to get the WB back in, should I just throw the VE graphs/cells up and visually see where to pull fuel to bring the BLM up from 117 back to 123-128?

Don't wanna wait to get the WB back in, should I just throw the VE graphs/cells up and visually see where to pull fuel to bring the BLM up from 117 back to 123-128?

Similar threads

- Replies

- 179

- Views

- 36K

- Replies

- 1

- Views

- 652