Pierre

New Member

- Joined

- Sep 19, 2019

Help!

I’m resealing my GNs engine and adding few power parts.

Engine is completely stock now.

I need help with gasket parts numbers to make sure I’ll get the right stuff.

Head gaskets, head bolts/studs.

Main seal and oil pan and timing cover gaskets.

Ad ones.

Ta49 turbo

60lb injectors/chip

212/212 cam

Double roller timing chain

Valve springs.

Do I need to port my heads?

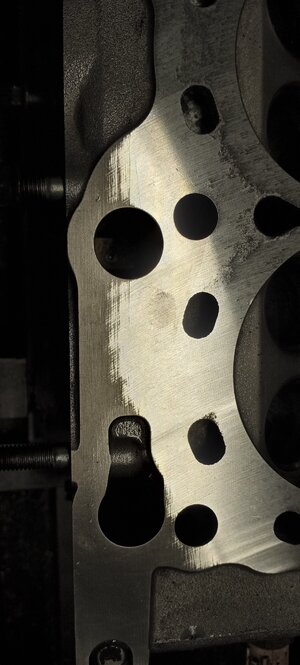

Also what all you think about the crank and rod bearings chape?

Thanks in advance!

I’ve been messing with this cars for a wile, but never too deep on the engine.

I’m resealing my GNs engine and adding few power parts.

Engine is completely stock now.

I need help with gasket parts numbers to make sure I’ll get the right stuff.

Head gaskets, head bolts/studs.

Main seal and oil pan and timing cover gaskets.

Ad ones.

Ta49 turbo

60lb injectors/chip

212/212 cam

Double roller timing chain

Valve springs.

Do I need to port my heads?

Also what all you think about the crank and rod bearings chape?

Thanks in advance!

I’ve been messing with this cars for a wile, but never too deep on the engine.