KevinB - I will send you a PM.

Pronto, GNVYUS 1, Ed Valvo - Revising the turbo chart will take some time, but it is on the to do list.

Ungrave - That is a very tough question to answer as I do not know of anyone who has purchased a Buick specific 3-bolt 5862 turbo. In my opinion, the 62mm CEA turbine wheel is not too big for a stock motor combination. Now given, 90% of the Buick owners do not realize the full potential of the turbo that they currently have. Nor do they maximize the combination before making a turbo change. This is why you occasionally see someone with a TA-49 or a TE-44 that have gone really fast. This is because they have maximized their combo around the power that the turbo is capable of supporting. This is not something that can be done overnight. Every aspect of their combination has been refined, tweaked and tuned to reach those unheard of ET's and speeds with the smaller turbos. I would not hesitate to run a 6262 turbo on a stock motor with bolt ons. Here is an example. Let's say someone is starting with a bone stock motor with valve springs and a timing chain that has been well maintained and passes all the checks and tests. And their goals are mid to low 11's in a full weight car. The 6262 would work great. But just bolting the turbo on and going for broke is not going to get you there. It takes supporting mods and a proper tune to get there. Supporting mods would be, a good aftermarket intercooler, fuel system, chip, 3" downpipe and exhaust. Then working on the suspension, a properly spec'd torque converter and sticky tires. And lastly, as a bare minimum a Scanmaster so you can at least have some idea of your state of tune while making a pass. A real bonus with this combo, would be to also incorporate a Power Logger into the mix. It will really help you fine tune the combo even further by being able to datalog the entire run. Now, you take this same combo and rebuild the motor, throw in ported heads or aluminum heads and a cam, retune it and now you have a mid to high 10 second capable combination. Combination and proper tuning are the keys to success with any Turbo Buick.

sixgun86 - A current turbo that would displace an older TE63, would be our 6266.

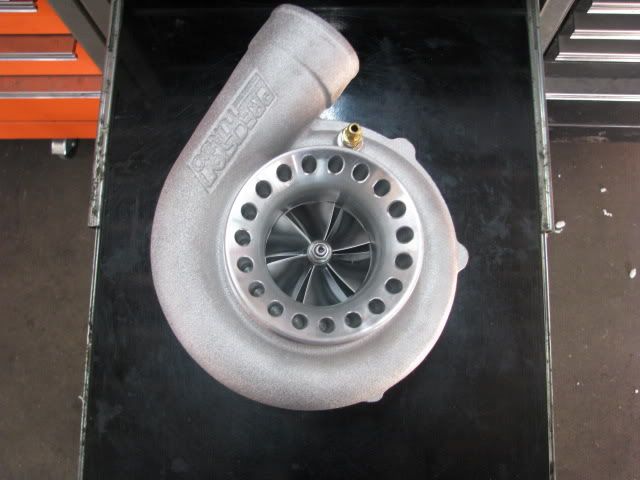

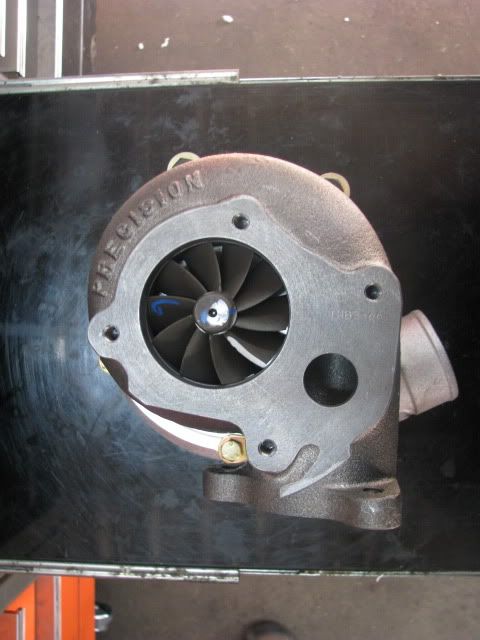

JT'sV6 - I will send you a PM. But to let others know, we have implemented an upgrade program as John Wilde mentioned earlier. We have been using the CEA turbine wheels in our 6262 units for some time now. The best way to find out if your 6262 has the CEA technology, would be to compare your turbine wheel to the one pictured above.

trick86 - Our CEA compressor wheel technology has been available with the Garrett stock appearing TA compressor cover, since we released them last year. Here is the thread started about the TA stock appearing CEA compressor wheel turbos.

http://www.turbobuick.com/forums/tu...os-latest-billet-ta-series-turbochargers.html As of now, the units that are available with both CEA billet compressor wheel and the CEA turbine wheel technology, would be our TA6262 and the TA6266.

tonysmach - I will send you a PM.

DoubleD - That is a very good question. These new CEA designed turbine wheels utilize the same metallurgy that all of our older turbine wheels have used. The main difference with the new CEA turbine wheels, is that they utilize the latest advancements in aerodynamics and are the first turbine wheels that have been designed in house. Yes, the previous designs were way too conservative.

As previously mentioned in our press release, back to back dyno testing has been done on various applications against our older 6262, 6265 and the 6765 turbos equipped with the CEA billet compressor wheels. This testing has been on going for the past 6 months with very favorable results. The new 62 CEA turbine wheel showed gains of 20 hp and the 66 CEA turbine wheel showed gains of up to 45 hp.

To my knowledge, I do not know of anyone who has done back to back testing on the new CEA 6766 vs CEA compressor wheel 6768 Buick specific 3-bolt turbos. But I'm sure we will hear results of that test soon.

Thank you all for your patience and I will post more updates as we get them. I will also be working on an updated turbo chart and will start a new thread once it is finished.

Let us know if you have any questions.

Patrick