Sal Lubrano

Active Member

- Joined

- Apr 26, 2002

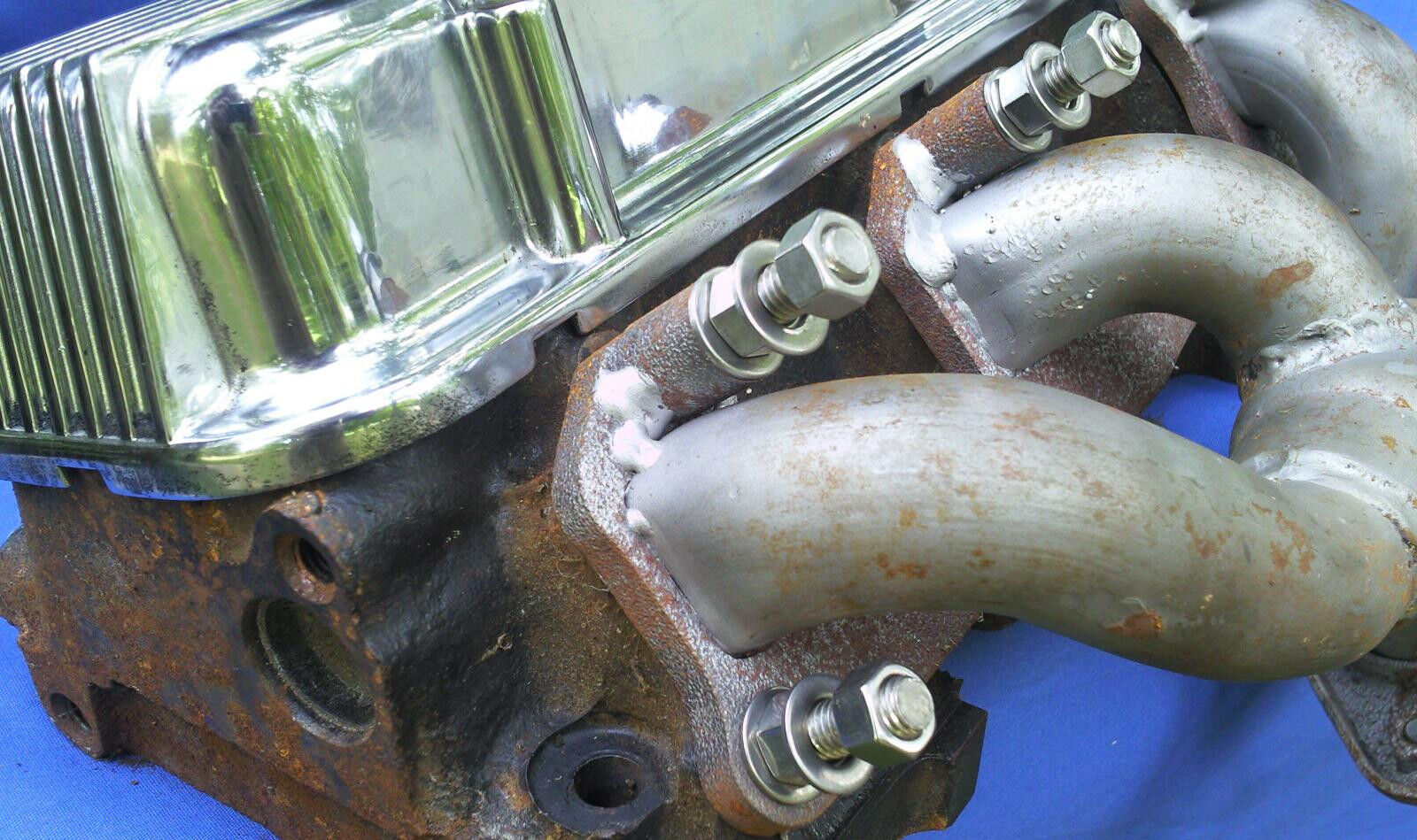

I have to pull off a set of exhaust headers which the bolts are really rusted and look like they have never been off in 20 years. Other than soaking them in good penetrating oil which would be my best bet.

1. Run the motor heating the head then break bolts free.

2. Use torch on the bolts with a cold motor.

3. Run motor heating the head and use torch on bolts.

Really don't want these bolts to break in the head. It will be a bad day if they do.

1. Run the motor heating the head then break bolts free.

2. Use torch on the bolts with a cold motor.

3. Run motor heating the head and use torch on bolts.

Really don't want these bolts to break in the head. It will be a bad day if they do.