Well since the main thing holding me up with my car is the rust that I need to repair, I decided to uncover it so I can figure out what I will need to do. These pictures are of my '85 Buick Regal T-type. The Doors and the rear wheel well in front and behind the rear tires.

Front corner of Drivers Door

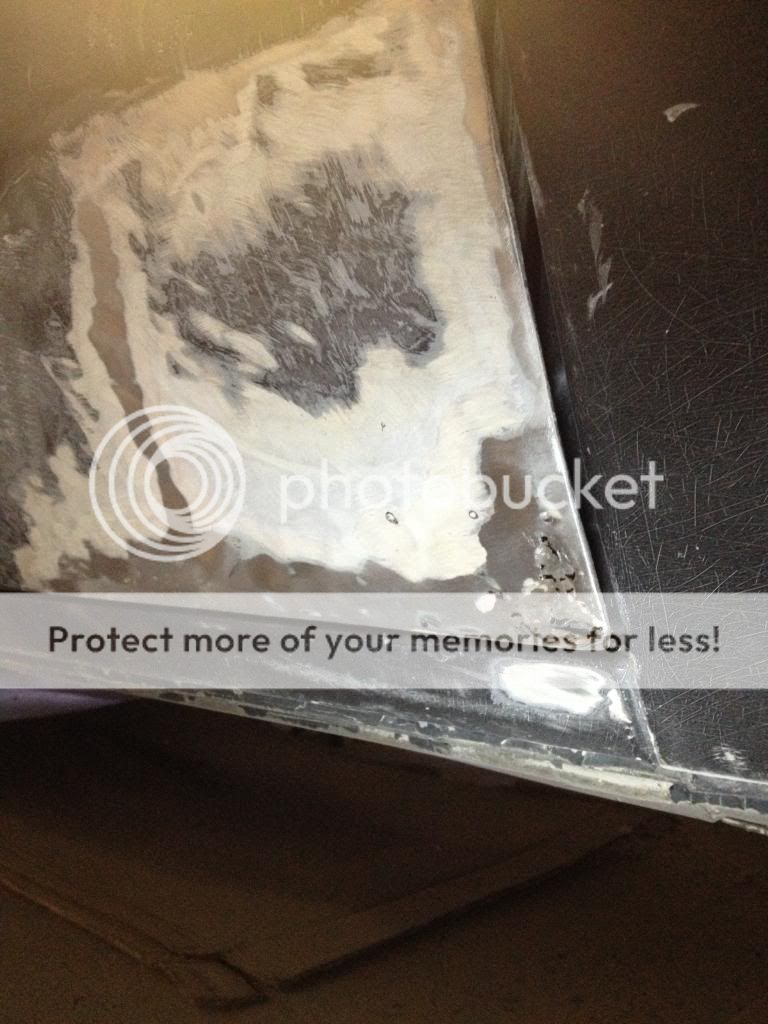

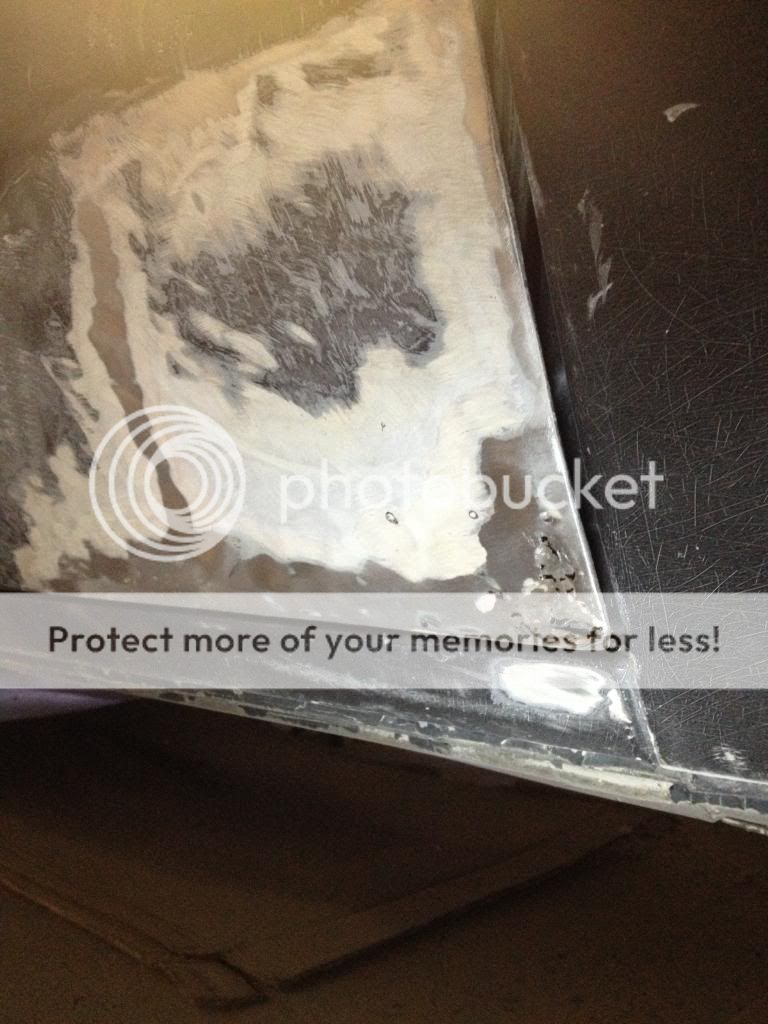

Rear corner of drivers Door, besides the rust looks like it has some type of dent that has a lot of what I believe to be filler in there. probably thicker than 1/4 inch....

Front of passenger Door - Maybe I can just weld these holes shut? Has a small dent too though

Rear of passenger Door - rust

This is the worst part of the car, its in front of the right rear wheel well, the wheel well arch itself looks like it seperated from the quarter also seemed like it was packed with cement?? It looked very porse and was a grey like color.

also seemed like it was packed with cement?? It looked very porse and was a grey like color.

So this is my first time doing anything like this, I did buy a Hobart 140 mig welder though, so I'm confident I can stitch weld panels in its place, I understand you don't want to over heat the metal so you jump around laying tack welds until everything is stitched together.

Any recommendations on what tools I should buy? I don't have any hammers or dollys.

Also What gauge sheet metal should I use for this?

I plan to strip this car all the way to metal, and I used my chemical stripper(aircraft stripper made by Klean Strip), its like mid 70's outside in temp and I applied the stuff on these areas shown in the picture so I could strip them, but this stuff works like crap! I mean its a vertical surface so I can't use plastic sheets on it.

So I ended up using a 3M paint stripper disc, its a gray fiber looking disc, using it in my Die grinder, and it doesn't seem possible to use these discs to strip any medium size areas to metal would take weeks!!!!

I think thats it for my questions so far!

Front corner of Drivers Door

Rear corner of drivers Door, besides the rust looks like it has some type of dent that has a lot of what I believe to be filler in there. probably thicker than 1/4 inch....

Front of passenger Door - Maybe I can just weld these holes shut? Has a small dent too though

Rear of passenger Door - rust

This is the worst part of the car, its in front of the right rear wheel well, the wheel well arch itself looks like it seperated from the quarter

So this is my first time doing anything like this, I did buy a Hobart 140 mig welder though, so I'm confident I can stitch weld panels in its place, I understand you don't want to over heat the metal so you jump around laying tack welds until everything is stitched together.

Any recommendations on what tools I should buy? I don't have any hammers or dollys.

Also What gauge sheet metal should I use for this?

I plan to strip this car all the way to metal, and I used my chemical stripper(aircraft stripper made by Klean Strip), its like mid 70's outside in temp and I applied the stuff on these areas shown in the picture so I could strip them, but this stuff works like crap! I mean its a vertical surface so I can't use plastic sheets on it.

So I ended up using a 3M paint stripper disc, its a gray fiber looking disc, using it in my Die grinder, and it doesn't seem possible to use these discs to strip any medium size areas to metal would take weeks!!!!

I think thats it for my questions so far!