Toby_Goodmk

Test Fit officianto

- Joined

- Dec 9, 2011

All my restoration body builds I document. However I have never documented an engine build like this. I have spent a considerable amount of resources in the past seeming to do work over. This time I am going about things in a different manner.

A true basket case delivered to the machinist

The bare 109 block

This block has a very nice thrust surface

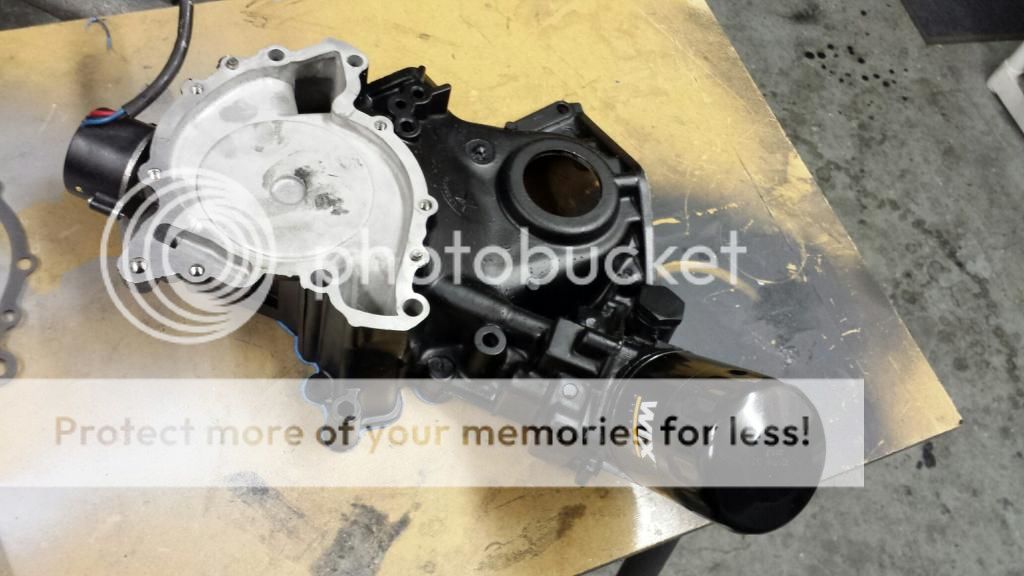

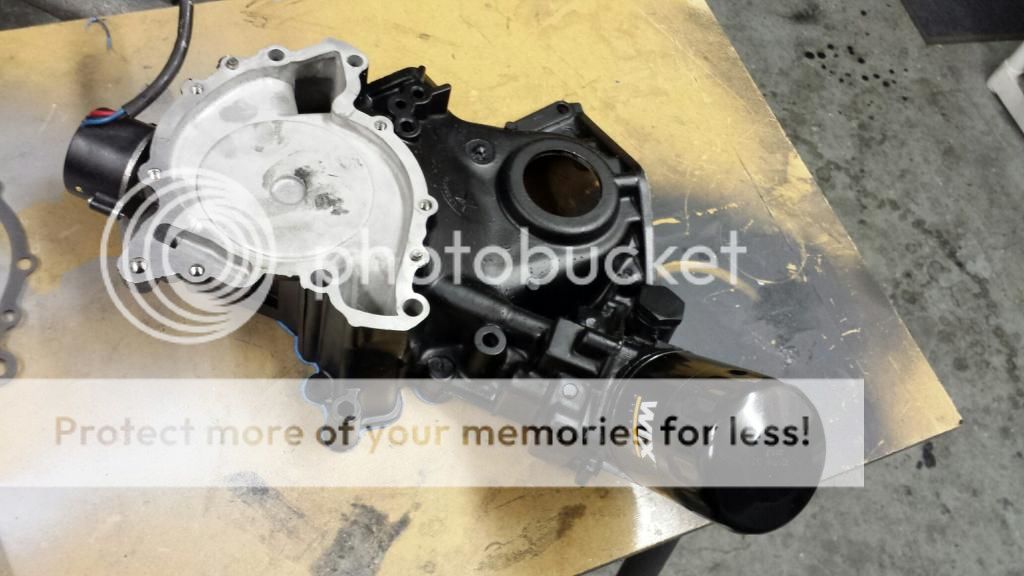

NOS timing cover ported and powder coated

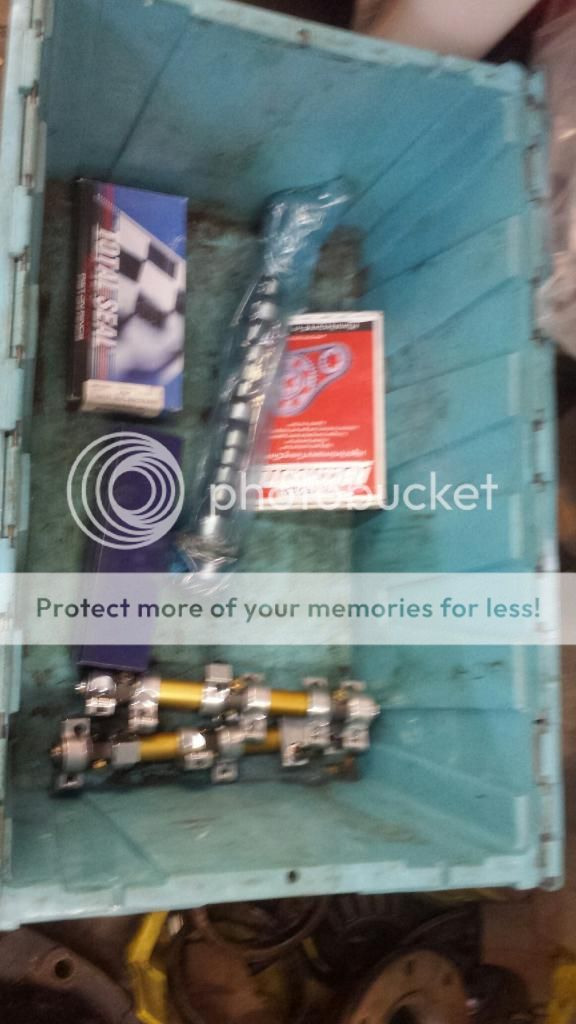

T & D 1:55 roller rockers will compliment the Champion irons, Comp 212/212 and TBP roller lifters

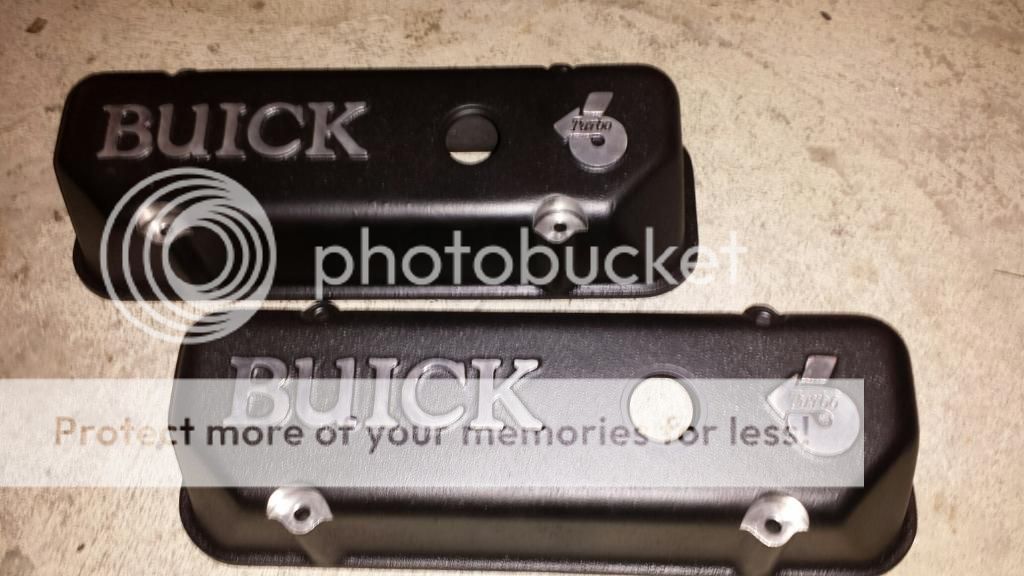

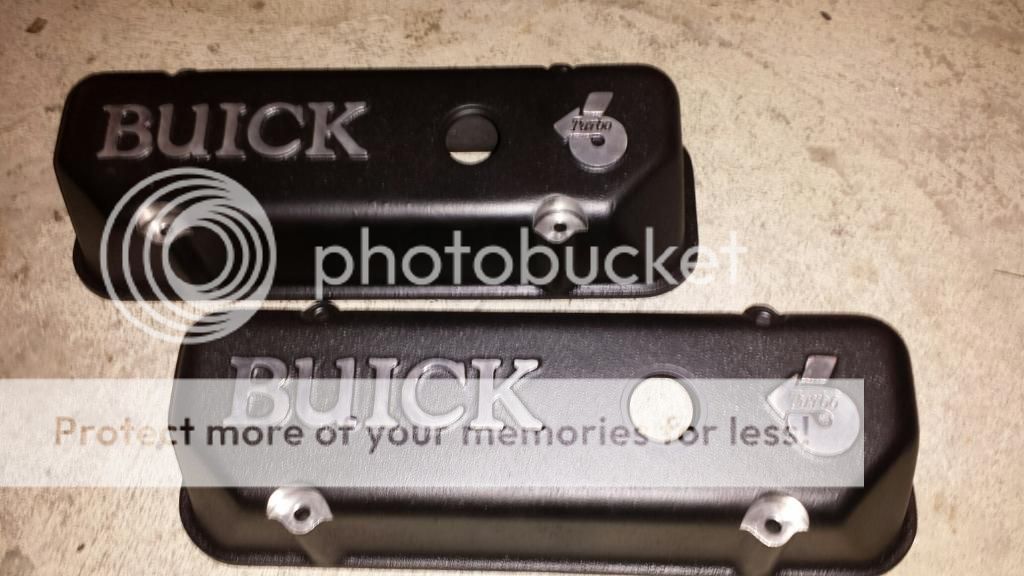

Blasted all the crap off my valve covers so I could powder coat them correctly and nicely

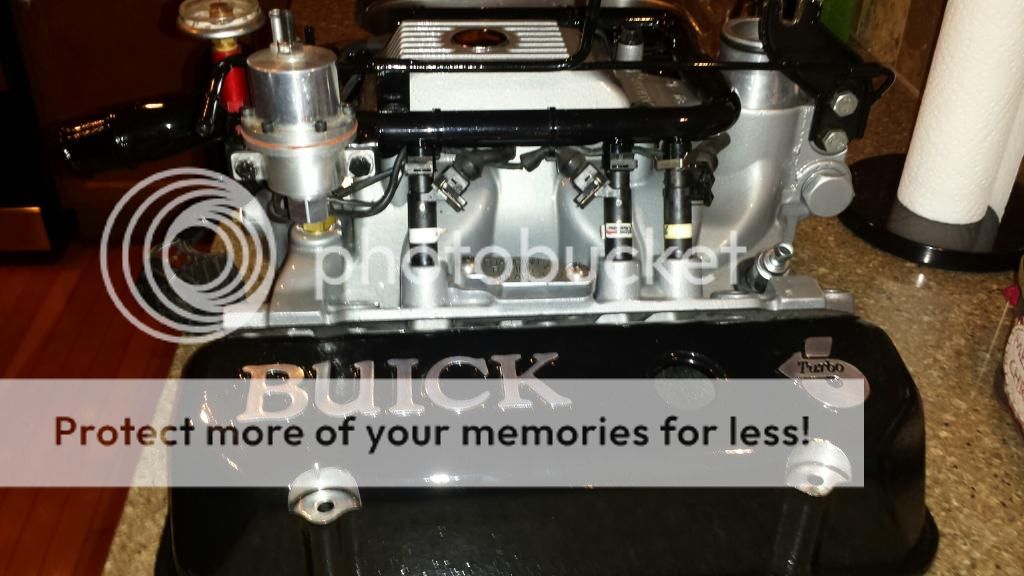

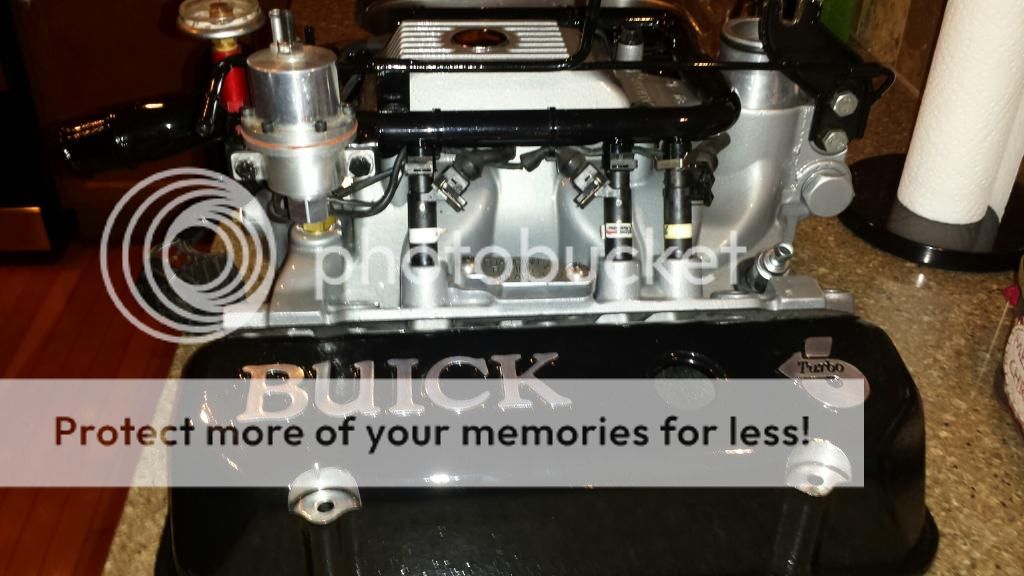

Powder coated and cleared the intake with the valve covers and all the brackets to the engine

61.5 MM turbo

Visited the machinist today delighted to see that the block was in the honing machine getting ready to get an align hone. He was able to save the billet caps we had on the SG1 block and put them into the new block

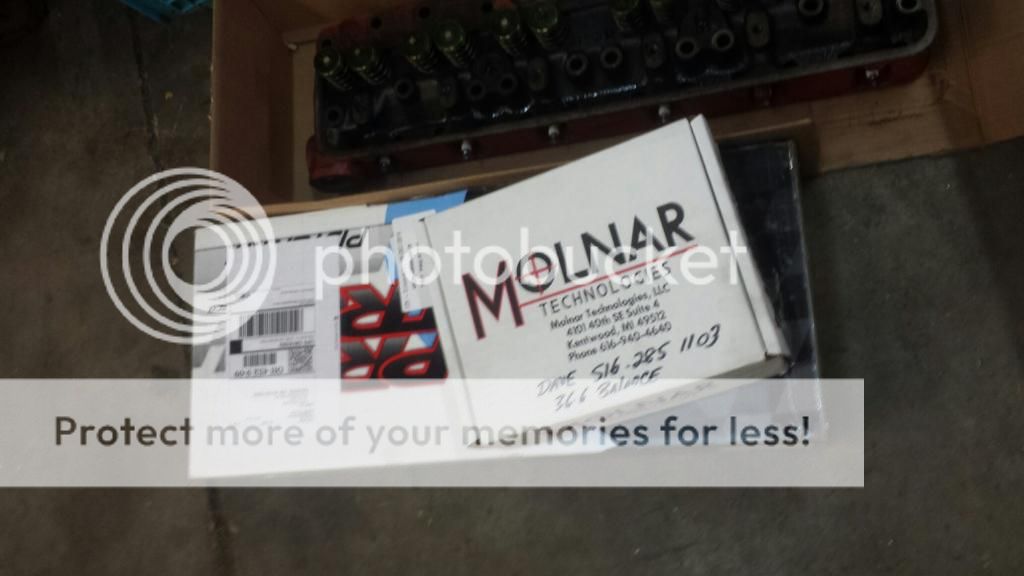

Come home today from work to find a present on the front door step for me

Next steps will be more powder coating to finish all the pulleys and such, then start trimming the engine bay with new silicone hoses in yellow....i know yellow?? It looks so cool and pops against black and chrome/silver.

A true basket case delivered to the machinist

The bare 109 block

This block has a very nice thrust surface

NOS timing cover ported and powder coated

T & D 1:55 roller rockers will compliment the Champion irons, Comp 212/212 and TBP roller lifters

Blasted all the crap off my valve covers so I could powder coat them correctly and nicely

Powder coated and cleared the intake with the valve covers and all the brackets to the engine

61.5 MM turbo

Visited the machinist today delighted to see that the block was in the honing machine getting ready to get an align hone. He was able to save the billet caps we had on the SG1 block and put them into the new block

Come home today from work to find a present on the front door step for me

Next steps will be more powder coating to finish all the pulleys and such, then start trimming the engine bay with new silicone hoses in yellow....i know yellow?? It looks so cool and pops against black and chrome/silver.