hello all. i am putting an Extreme Automatics 200-4R behind my slant 6 powered 1984 Dodge D100 short bed..................

ok, now that you have stopped LAUGHING, here are some details of the truck;

1984 Dodge D100 shorty, about 3800 lbs. (i think close to the Buicks?)

1967 slant 6 225, bored .084, long rods (from a 198), Wiseco Pro-Tru forged pistons, forged crank

Oregon Cams grind #346 - .262/.252 @.020, 106 lsa, installed at 104 icl., .476/.479 lift at valve

(the slant likes more intake duration)

oversize stainless valves, 1.70/1.44, head ported

9.8:1 scr/8.2:1 dcr

edelbrock performer 500cfm, offenhauser 4 barrel intake, hooker 6/1 header w/2.5" outlet and 2.5 single exhaust.

desktop dyno says 225hp/350ft/lbs.

3.92 sure-grip rear/28" tall tires

any advice with the 200-4R install would be great.

if interested, the thread at slantsix.org is here;

slantsix.org/forum/viewtopic.php?t=53702&sid=c80e656f9b3990da76c8d61cdf8f7776

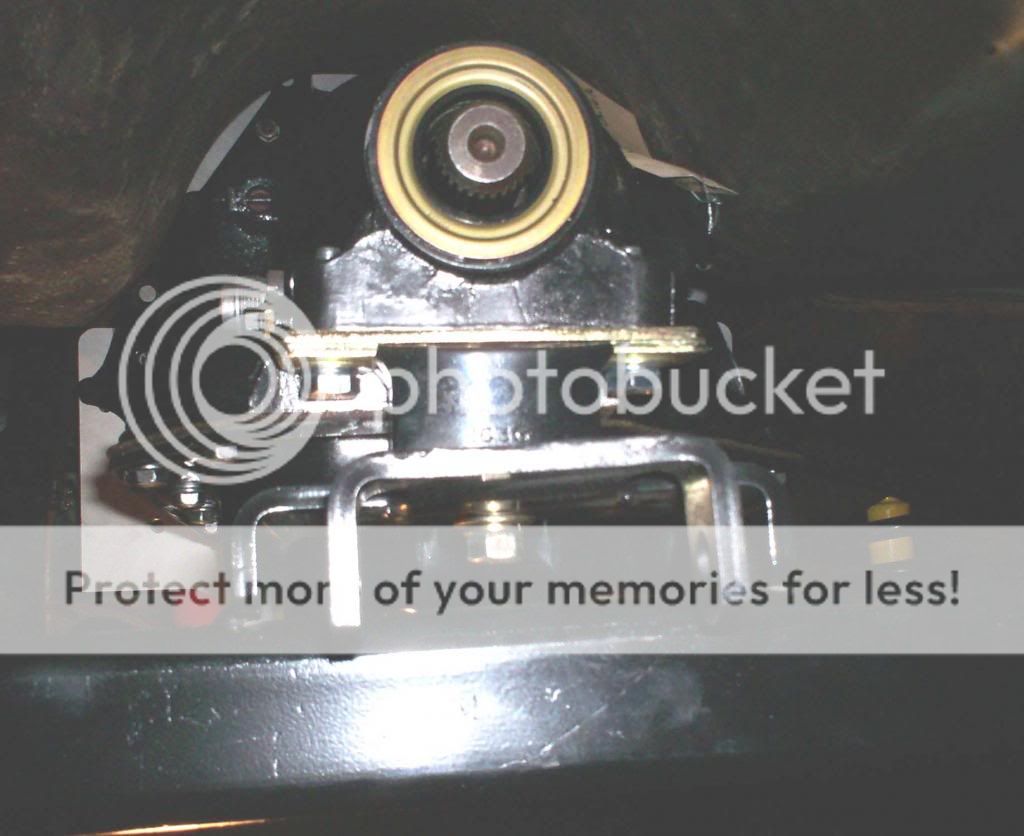

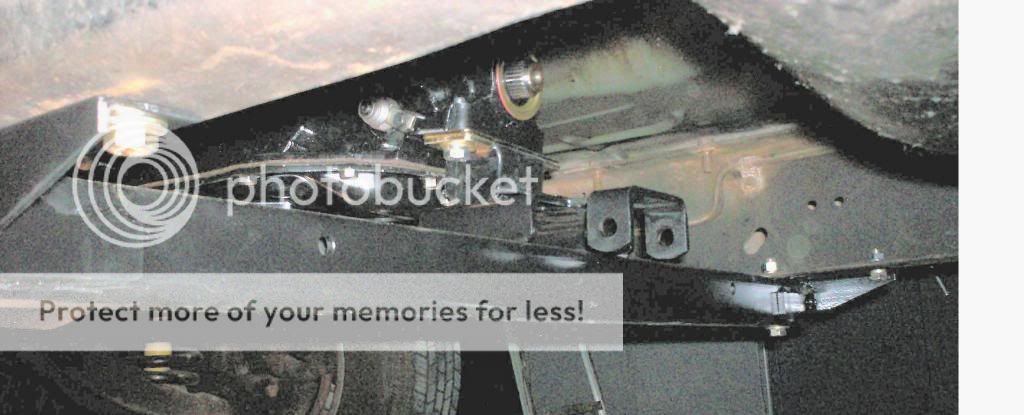

and photos here;

s837.photobucket.com/user/akbmotorsports/library/?sort=3&page=1

thanks and have a great day, andy

ok, now that you have stopped LAUGHING, here are some details of the truck;

1984 Dodge D100 shorty, about 3800 lbs. (i think close to the Buicks?)

1967 slant 6 225, bored .084, long rods (from a 198), Wiseco Pro-Tru forged pistons, forged crank

Oregon Cams grind #346 - .262/.252 @.020, 106 lsa, installed at 104 icl., .476/.479 lift at valve

(the slant likes more intake duration)

oversize stainless valves, 1.70/1.44, head ported

9.8:1 scr/8.2:1 dcr

edelbrock performer 500cfm, offenhauser 4 barrel intake, hooker 6/1 header w/2.5" outlet and 2.5 single exhaust.

desktop dyno says 225hp/350ft/lbs.

3.92 sure-grip rear/28" tall tires

any advice with the 200-4R install would be great.

if interested, the thread at slantsix.org is here;

slantsix.org/forum/viewtopic.php?t=53702&sid=c80e656f9b3990da76c8d61cdf8f7776

and photos here;

s837.photobucket.com/user/akbmotorsports/library/?sort=3&page=1

thanks and have a great day, andy