- Joined

- Feb 18, 2006

The long wire piece is the end of a dipstick, no? The other debris I'm not sure but the bearing failure is more than likely the result of the pick up being clogged. The system was starved for oil.

How do you tell if there are stock TTA heads on the car? I don' think the heads on TTA were stock anymore. The previous owner said that was one of the upgrades, bigger heads. Is there a serial number or something on them?

I think they are P/N 25536702, ported heads for a TTA. Does this make it better for the higher compression of the pistons?

Here are a couple of pics of the heads. These are the only numbers I found on them.

I think the 702 casting number is for original tta heads.

Sure...I am not going to race the car, would like to get it set and the boost set so it if more of a reliable street car to take to car shows and cruise nights.

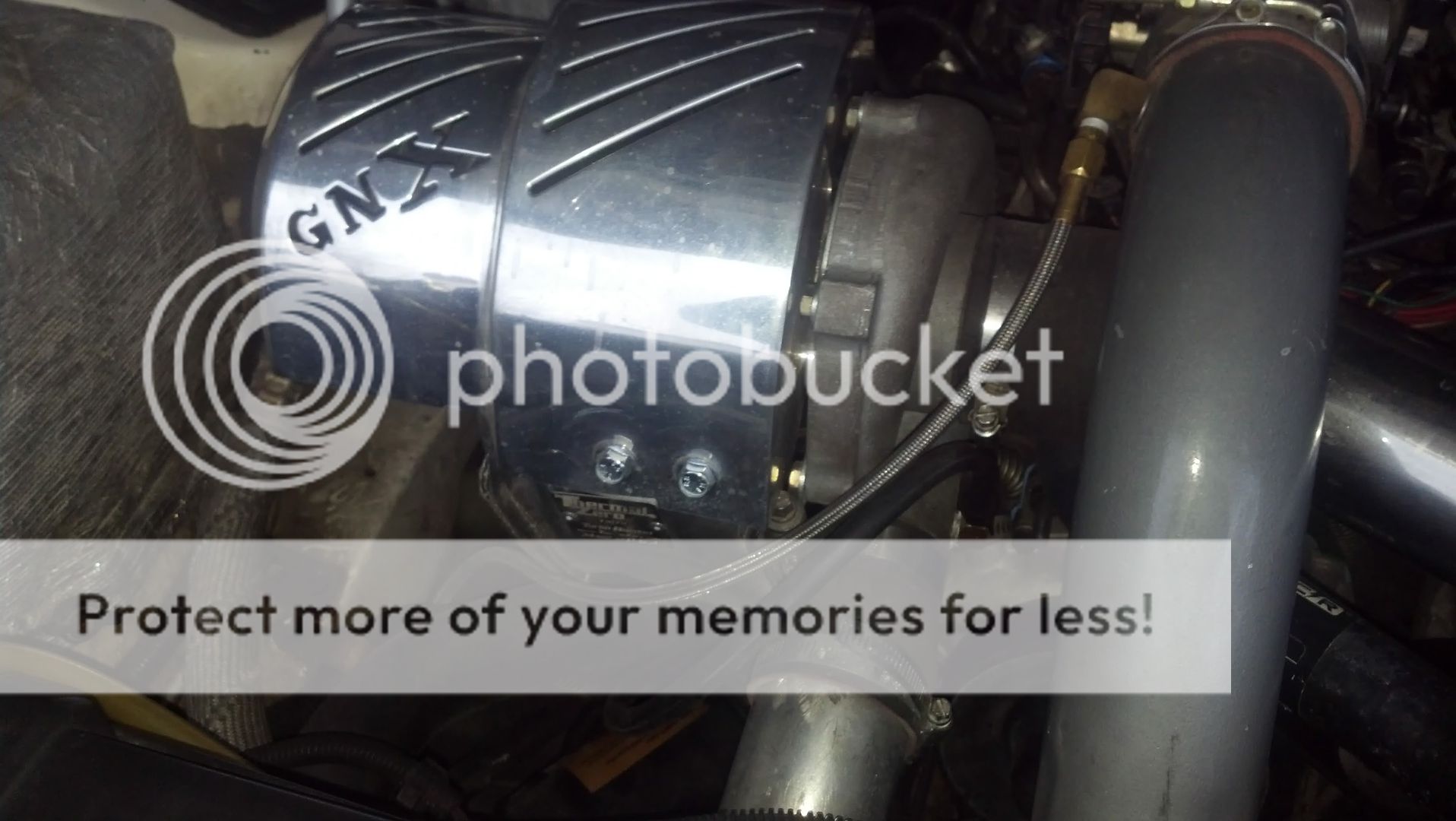

Fixed the vacuum leak going to the HVAC temp selector. We unplugged this vac line and the hissing away and we capped it. I am assuming from the diagram that there are two vac lines that go through the front passenger firewall, one for the hvac and the other for cruise control. I am guessing we capped the cruise as it did not work. HVAC works perfect now. See pic of the two lines with the one capped under the red wire in the middle of the pic.

The turbo gauge on the dash is not working at all now. I didn't before we started today. I turned up the boost control controller in the car and the flutter is not as bad. The big turbo gauge on the pillar still works. From my research, the turbo guage in the car is electric and works off map sensor in the upper front passenger wall. I checked the vac line and the connections and tested again and still no boost on the controller. It has a working vac line to it, so I am guessing the map sensor is bad. Could this cause the turbo flutter?

Also, what is this line above the map sensor. It has two white wires that go into a green clip, almost looks like a fusable link and from a pic I saw of someone elses on here, their's is stuck in the black protective wire cover and electric taped in. Does anyone know what this is with the green tip on it?