Maybe this will help somebody out. I used a mig welder, wire wheel, cutting wheel and a metal flanger/hole punch.

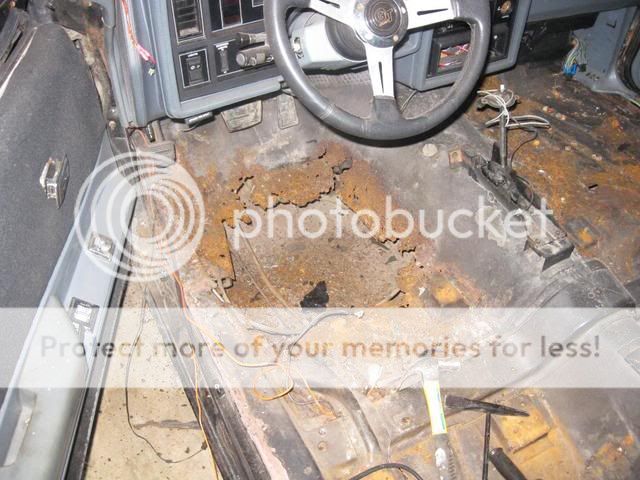

Much to my amazement, I found out the perforated passenger side rocker panel wasn't standard equipment from the factory.

I ordered a replacement panel from gbodyparts.com and decided to fix it myself.

Wire wheel the top and bottom lips of the rocker panel to expose the spot welds and drill them out.

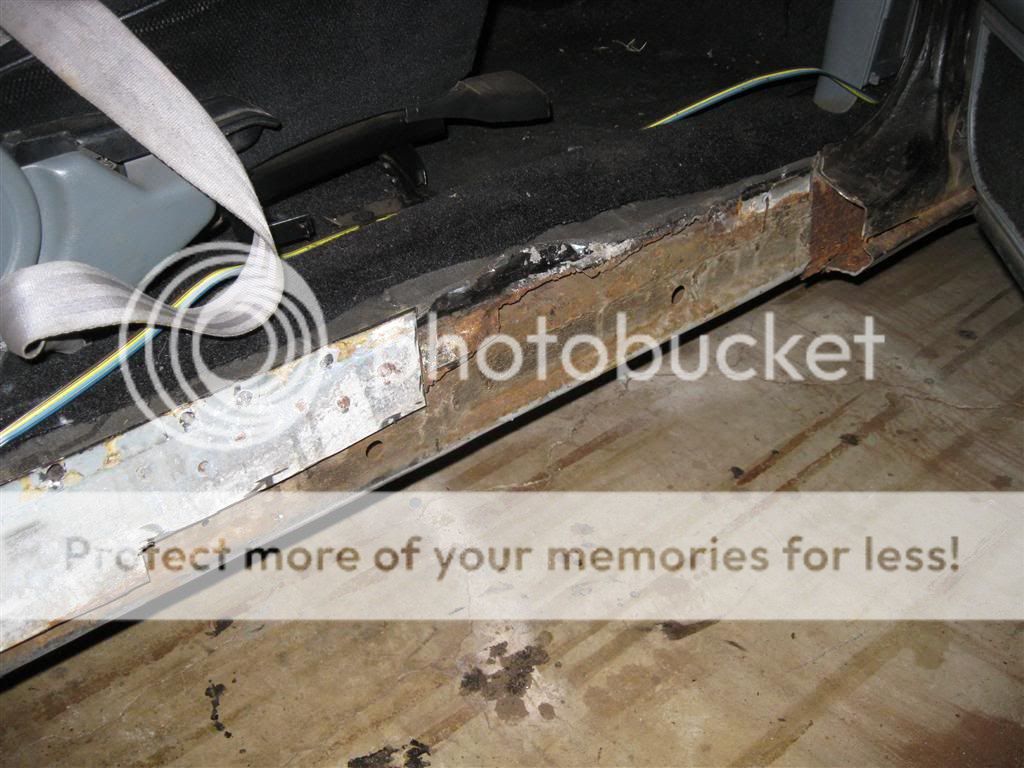

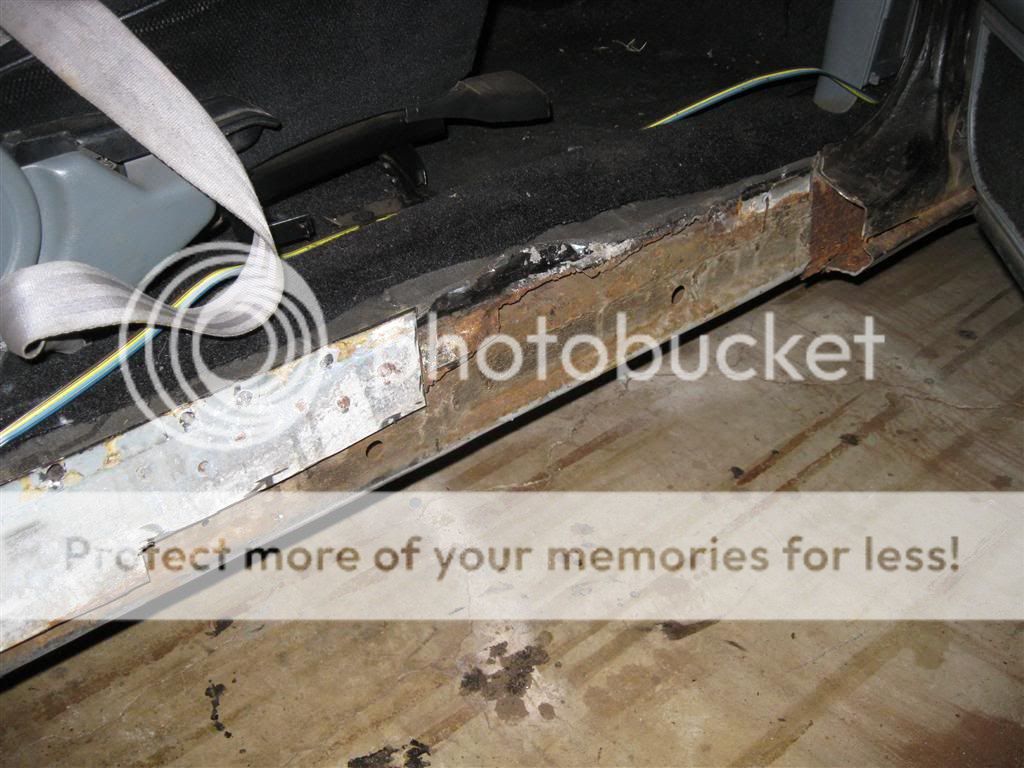

I used a cutting wheel to cut the rocker where it meets the door frames or pillars. You can see the joint here. The rocker runs underneath, but there was no rust there so I didn't worry about it.

Mommy, please make it stop! Rust had taken half of the face plate where the rocker mounts.

Here I'm cutting out all the bad metal. I eventually cut out most of what was under the front pillar. I used a wire wheel to remove all the remaining rust and grime on the frame and metal I could save.

I ended up having to cut back into the edge of the floor pan and weld a new L-shaped metal section that hangs down so I could weld the new face plate metal onto it. I forgot to get a photo of that. Also forgot to get a pic of the new primer on the frame and underneath the pillars.

It looks like the original metal was 22 gauge. I bought a sheet of new 22 gauge at Lowe's. The face plate is 5 inches in width with an angle at the bottom for the bottom of the new rocker to attach. I put a 1/2 inch 45 degree angle along the bottom of the new section.

The rest of the metal I overlapped with a flange tool instead of trying to butt-weld it. Much Easier.

Be sure clean the metal before painting to remove grease. I used Acetone. I forgot to do this and the paint was already bubbling up in places. I wire wheeled it, cleaned and repainted. Be sure to paint the back of the face plate before welding it on.

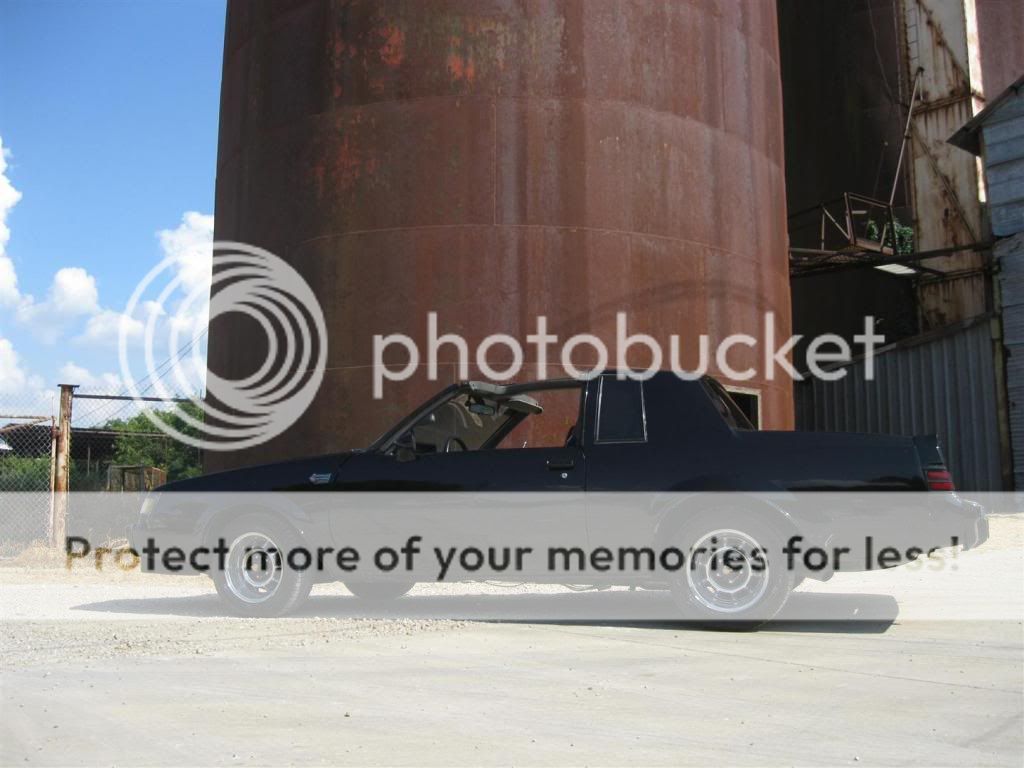

I always have to paint it all black for some reason.

Here is the angle I put on the bottom of the new metal. I was able to use a sheet metal bender at work. After Trial fitting the new rocker, I found I needed to take away some of the angle so the bottom of the new rocker rested against it. It was really easy with channel locks.

I found the top lip of the new rocker isn't flush with the mounting plate like the original. This was not problem. I used a metal punch to make holes where I will spot weld the rocker on the top and bottom.

Now for the trial fit. I sat there with a grinder taking off metal here and there to make sure it fit perfectly. Then tack weld two spots on the top and two on the bottom. Remove all clamps and shut the door to make sure the line and gap between the bottom on the door and rocker panel is uniform and looks good.

Then I filled in my spot welds on the top and bottom only. Don't weld any part of the rocker panel yet to the pillar supports/door frame. This way you can tweak the panel to make sure it's flush and even with the front fender and rear fender. However, check this to make sure they are flush before you spot weld, but you can still tweak if needed. Mine stayed flush and didn't move from all the heat from spot welding.

Now I need to go back and finish welding the new panel onto the pillar/door frames, grind it to make it look nice as possible and then use some body filler to hide the welded joint between the rear fender and rocker panel, the only joint visible with the door closed.

Much to my amazement, I found out the perforated passenger side rocker panel wasn't standard equipment from the factory.

I ordered a replacement panel from gbodyparts.com and decided to fix it myself.

Wire wheel the top and bottom lips of the rocker panel to expose the spot welds and drill them out.

I used a cutting wheel to cut the rocker where it meets the door frames or pillars. You can see the joint here. The rocker runs underneath, but there was no rust there so I didn't worry about it.

Mommy, please make it stop! Rust had taken half of the face plate where the rocker mounts.

Here I'm cutting out all the bad metal. I eventually cut out most of what was under the front pillar. I used a wire wheel to remove all the remaining rust and grime on the frame and metal I could save.

I ended up having to cut back into the edge of the floor pan and weld a new L-shaped metal section that hangs down so I could weld the new face plate metal onto it. I forgot to get a photo of that. Also forgot to get a pic of the new primer on the frame and underneath the pillars.

It looks like the original metal was 22 gauge. I bought a sheet of new 22 gauge at Lowe's. The face plate is 5 inches in width with an angle at the bottom for the bottom of the new rocker to attach. I put a 1/2 inch 45 degree angle along the bottom of the new section.

The rest of the metal I overlapped with a flange tool instead of trying to butt-weld it. Much Easier.

Be sure clean the metal before painting to remove grease. I used Acetone. I forgot to do this and the paint was already bubbling up in places. I wire wheeled it, cleaned and repainted. Be sure to paint the back of the face plate before welding it on.

I always have to paint it all black for some reason.

Here is the angle I put on the bottom of the new metal. I was able to use a sheet metal bender at work. After Trial fitting the new rocker, I found I needed to take away some of the angle so the bottom of the new rocker rested against it. It was really easy with channel locks.

I found the top lip of the new rocker isn't flush with the mounting plate like the original. This was not problem. I used a metal punch to make holes where I will spot weld the rocker on the top and bottom.

Now for the trial fit. I sat there with a grinder taking off metal here and there to make sure it fit perfectly. Then tack weld two spots on the top and two on the bottom. Remove all clamps and shut the door to make sure the line and gap between the bottom on the door and rocker panel is uniform and looks good.

Then I filled in my spot welds on the top and bottom only. Don't weld any part of the rocker panel yet to the pillar supports/door frame. This way you can tweak the panel to make sure it's flush and even with the front fender and rear fender. However, check this to make sure they are flush before you spot weld, but you can still tweak if needed. Mine stayed flush and didn't move from all the heat from spot welding.

Now I need to go back and finish welding the new panel onto the pillar/door frames, grind it to make it look nice as possible and then use some body filler to hide the welded joint between the rear fender and rocker panel, the only joint visible with the door closed.