BARRACUDA1968

Well-Known Member

- Joined

- May 4, 2011

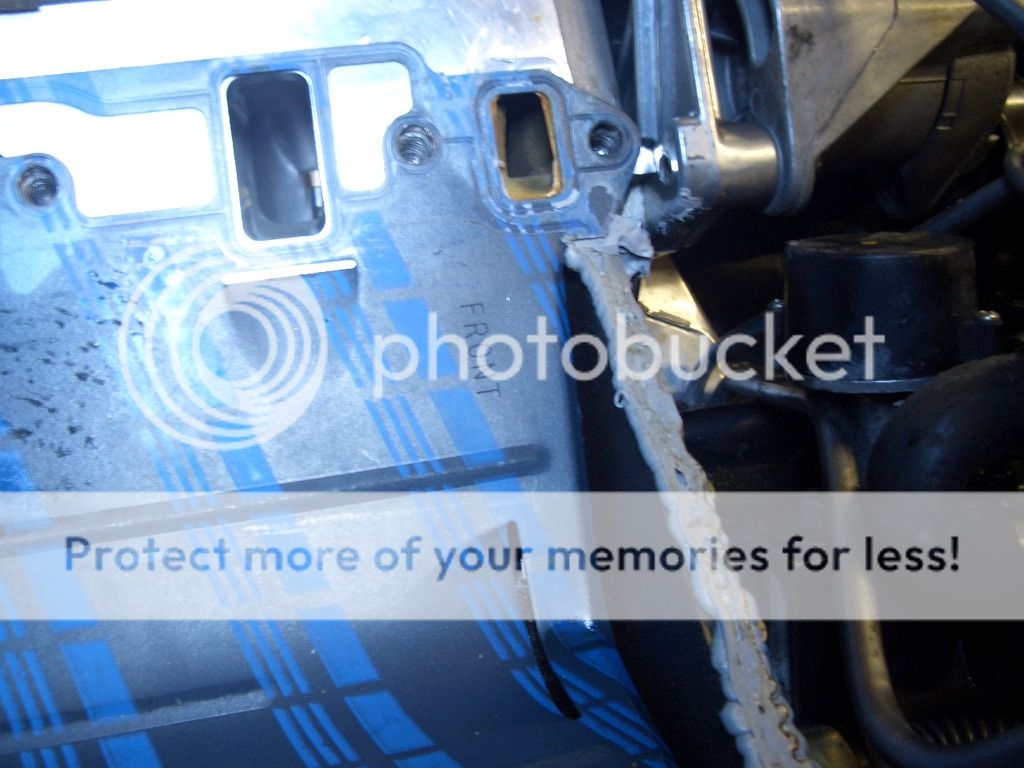

Been fighting an oil leak at the intake ever since I put the motor back in this spring. Leaked from day one. My engine builder used the rubber gaskets on the block so when I pulled it the first time I just ran silicone and re installed it. Still leaked out of all four corners, better but still leaked. Got sick of it and pulled the intake again, spent hours cleaning and using a pick in the four corners to get the surface clean and oil free. Finished it last night after letting the silicone set up over night. Went for a drive and I'll be a sum bit$h if it isn't still leaking just like before.

I'm using Cometics and I think part of the problem is oil pools up in the corners on top of the head gasket and some how makes its way around the silicone lower on the head??? Then it trails down the head gasket around the corner of the lower head and drops off at the center of the block on both sides. I ran a bead of the right stuff down the back of the head hoping to solve the issue but didn't work. The oil found a way.

I can't stand oil leaks so it drives me nuts. I know it's a TB and they're supposed to leak whatever but I hate it.

I know the best way to fix my issue is to pull the heads and either clearance the Cometic if that's the problem or just pull the motor so I can get a good look at fitment between the head/intake and block. My blocks been decked, intake been milled and now I have new TA heads. Odly enough the intake fit's perfect.

I'm kind of bummed about the whole deal honestly. I've done 20 intakes over the years and have never had one leak.

I did try and fit the rubber gaskets on the motor before I went with silicone. The front seemed to fit a lot better than the rear. Both were very distorted trying to get them wedged in the head and block area. Seems like the head gasket is in the way? and the gasket "wedge" was much larger than the area I have for it to fit in to. I typed this so you guy's know I tried to work with the rubber gaskets but it just didn't feel right to me.

I'm tired of working on it so I'm going to drive it the rest of the season. As of now the leaks are minor. Maybe more boosting will make it worse so I'll have to deal with it.

I did read doing a search a member with a similar problem to mine used an oil sealer additive and went straight 40 wt oil. Seemed to do the trick for him. I'm hesitant to try this because most snake oils don't work as advertised. I'll fix it right later if I can get the oil leaks slowed way down or stopped. Yes I'm grasping for straws but there is a product or technique that can get me by throw it out there. I'm all ears.

Thanks Brett

On a good note the car hauls A$$ majorly!!!

I'm using Cometics and I think part of the problem is oil pools up in the corners on top of the head gasket and some how makes its way around the silicone lower on the head??? Then it trails down the head gasket around the corner of the lower head and drops off at the center of the block on both sides. I ran a bead of the right stuff down the back of the head hoping to solve the issue but didn't work. The oil found a way.

I can't stand oil leaks so it drives me nuts. I know it's a TB and they're supposed to leak whatever but I hate it.

I know the best way to fix my issue is to pull the heads and either clearance the Cometic if that's the problem or just pull the motor so I can get a good look at fitment between the head/intake and block. My blocks been decked, intake been milled and now I have new TA heads. Odly enough the intake fit's perfect.

I'm kind of bummed about the whole deal honestly. I've done 20 intakes over the years and have never had one leak.

I did try and fit the rubber gaskets on the motor before I went with silicone. The front seemed to fit a lot better than the rear. Both were very distorted trying to get them wedged in the head and block area. Seems like the head gasket is in the way? and the gasket "wedge" was much larger than the area I have for it to fit in to. I typed this so you guy's know I tried to work with the rubber gaskets but it just didn't feel right to me.

I'm tired of working on it so I'm going to drive it the rest of the season. As of now the leaks are minor. Maybe more boosting will make it worse so I'll have to deal with it.

I did read doing a search a member with a similar problem to mine used an oil sealer additive and went straight 40 wt oil. Seemed to do the trick for him. I'm hesitant to try this because most snake oils don't work as advertised. I'll fix it right later if I can get the oil leaks slowed way down or stopped. Yes I'm grasping for straws but there is a product or technique that can get me by throw it out there. I'm all ears.

Thanks Brett

On a good note the car hauls A$$ majorly!!!