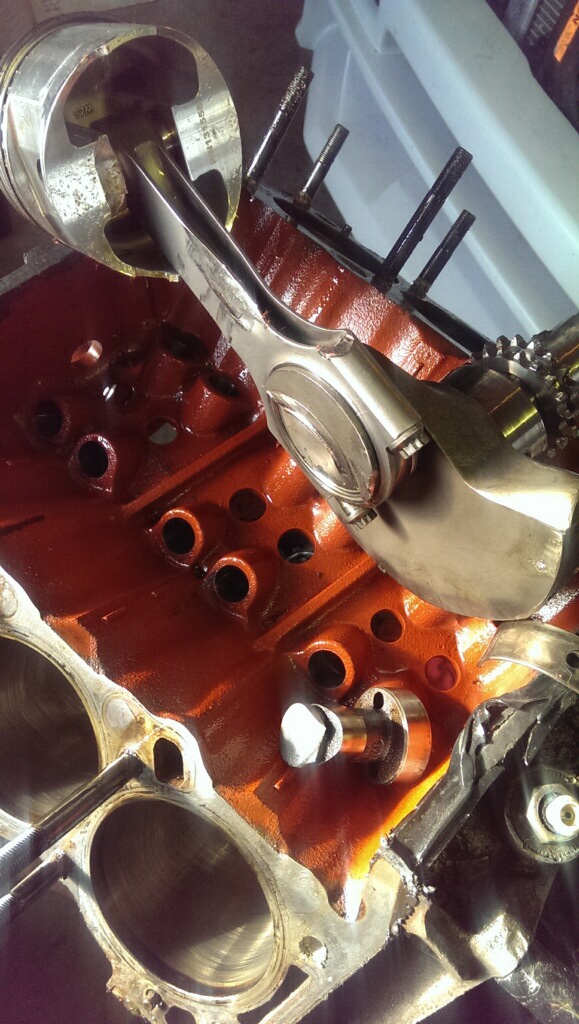

So my 85 Buick t-type (hot air), im debating rebuilding it myself, or at least having the long block put together.

Goals: faster, not a 9 second car, probably not even a 10 second car.

The trans will be built, rearend stock currently, but will address it once i research that.

Reason why im rebuilding it, is because of a ticking noise when its warmed up and driven for a couple miles, its coming from rear of oil pan area.

Id like to do a forged crank, and billet mains for 1,2,3 as ive read rear main isnt necessary.

What im wondering is, what i can get away with reusing, and i know its a stupid question, how much power can the stock pistons and rods handle? Probably use stock cam, dont know if i could afford going roller at this time. Converter might stay stock too

I guess also the block, curious how much it can take, im pretty sure its a 109 block, i know its not supposed to be since its an 85.

Currently car is running on e85, 80# injectors, maf translator, newer maf, dw300 pump, TA33 turbo.

Goals: faster, not a 9 second car, probably not even a 10 second car.

The trans will be built, rearend stock currently, but will address it once i research that.

Reason why im rebuilding it, is because of a ticking noise when its warmed up and driven for a couple miles, its coming from rear of oil pan area.

Id like to do a forged crank, and billet mains for 1,2,3 as ive read rear main isnt necessary.

What im wondering is, what i can get away with reusing, and i know its a stupid question, how much power can the stock pistons and rods handle? Probably use stock cam, dont know if i could afford going roller at this time. Converter might stay stock too

I guess also the block, curious how much it can take, im pretty sure its a 109 block, i know its not supposed to be since its an 85.

Currently car is running on e85, 80# injectors, maf translator, newer maf, dw300 pump, TA33 turbo.