northerngn

Master Monkeywrench

- Joined

- Oct 8, 2006

Tom, I'll call tomorrow and post my findings...

-Dan

-Dan

I hear ya on that one. What kind of 60' time is that assuming? Although, Eric seems to know his stuff, especially regarding what he sells. Wouldn't surprise me at all if it's the same design as this DW pump. Maybe it even comes from the same supplier overseas.

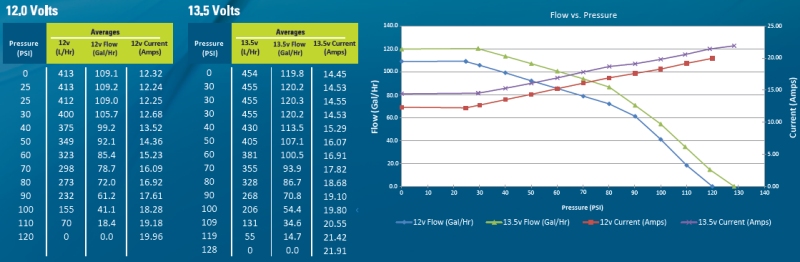

From the flow data on the DW website, it says the 301 pump supports 370 L/hr with 18V supplied to it at 70 psi, like you would get from a boost-a-pump. Say you want to run 80lb injectors, at 100% duty cycle that would be 480 lb/hr total, right? I would hope they used gasoline in their testing, or at least something with a similar viscosity. Using a density of 737 kg/m^3 for regular vehicle gasoline, I get that this pump at these conditions could flow just over 600 lbs/hr, more than enough to support 80 lb injectors at full duty cycle. Can someone do their own calculations to see if they get the same answer? I'm new to this fuel system stuff.

I agree with Tom that you should not build your system so you are always pushing it to the limits. Seems like this pump can support 80s with a volt booster if my math was correct. I certainly wouldn't try supporting 120s. How much power 80s can support on E85, I don't know. The veterans on here can probably better answer that.

Tom, I'll call tomorrow and post my findings...

-Dan

Dividing the pump supply of 370 L/hr by 3.8, I get 97 gal/hr. Using roughly 6 lbs/gal for gas, I get 582 lb/hr, yet it is still more than the injector demand of 480 #/hr. Should be ok.

Dan:

Thanks.

It's due to people like you, that are willing to go to the extra time and effort to share their info that makes a site like this so valuable.

When you get near the limits of a pump the injectors will have to work harder. If the fuel pressure can't be maintained at WOT and in closed loop, the duty cycle will increase. If you are already operating at or near the physical limits of any component in your system, there is a chance that there could be serious consequences.

I should have not replied with a quote from a pump when referring to injectors. I don't have a problem with your math or reasoning if all proves out. I should have stated that up front. If you assume the 18 volt delivery rate and it proves out not just initially, but over time, then I am happy for you. Good luck. I would like to discourage overly optomistic thinking. It sometimes can be dissapointing in the end.If you will notice that the injector demand of 480 lb/hr represents 6 of 80#/hr injectors at 100% duty cycle (so duty cycle can't increase any more, it's the worst case) and is less than the pump's supply of 580 lb/hr (by 100 lb/hr or almost 20% margin) then you will realize that the fuel pressure will be maintained.

I ran a single DW301 for a few weeks with nothing in line but the filter. I assume it had a built in check valve or it would not hold fuel pressure with key on after the pump shut off. I don't think dual DW301's will fit through the hole in the gas tank?Does anyone know for sure if dual DW 300-1 pumps can be run without a in-line check valve? I don't know if the DW pumps have a check valve built in. Thanks for any info!!