b4black

Well-Known Member

- Joined

- May 24, 2001

This is an old thread (2006) from the other board, but I thought it might be helpful over here.

OK, so after a year or so, I said to hell with ATR helping me out and took matters into my own hands. Last fall I picked up a used 84/85 ATR 2.5" pipe and figure I could get someone to weld a new top to it.

The ATR pipe is nice. It doesn't look bigger, but it's not double walled like the stock DP and is much bigger internally. It bolts the the stock 84/85 elbow, which uses the same donut gasket as our cars. That got me thinking.

Today I cut a section of the pipe out in the middle. If you bolt the bottom to the converter and the top to the turbo (using a 3-bolt flange instead of the 84/85 2-bolt flange) they come real close to meeting. I then connected them with so cheesy flex pipe and it fits. Actually the flex joint doesn't look bad and once I get some decent clamps on it, it will look good.

The ATR is pipe not too expensive. I think they are $135 new and I paid $50 for a good-used. A cut off wheel, a flex pipe and some clamps is all that is needed. Also, you either need to get the right 3-bolt flange or cut it off the stock pipe. Best part is that it's a DIY job - no exhaust shop needed.

Getting the stock pipe out is work. I had to removed the crossover and passenger side manfold. AC comporessor might get in the way if you have one.

George,

I have a 1983 Turbo Buick Regal. This is the early carbureted version. I and others are very interested in a larger 2½" downpipe. I have heard reports that you make a very nice 2½" DP for the 84/85 Turbo Regal, was hoping you would consider making one for the earlier cars. The downpipes are very similar. Only the top portion is different and it is actually less complicated than the 84/85 DP.

Dowpipes interchange for all 1978 thru 1983 Turbo Buicks except Rivieras (FWD). I know there would seem to be very little demand for early Turbo Buick performance parts, but I believe that quite a few people would be interested in this. The small stock downpipe is one of our primary week spots.

Here are some comparison pictures. I can send you an stock downpipe if it helps.

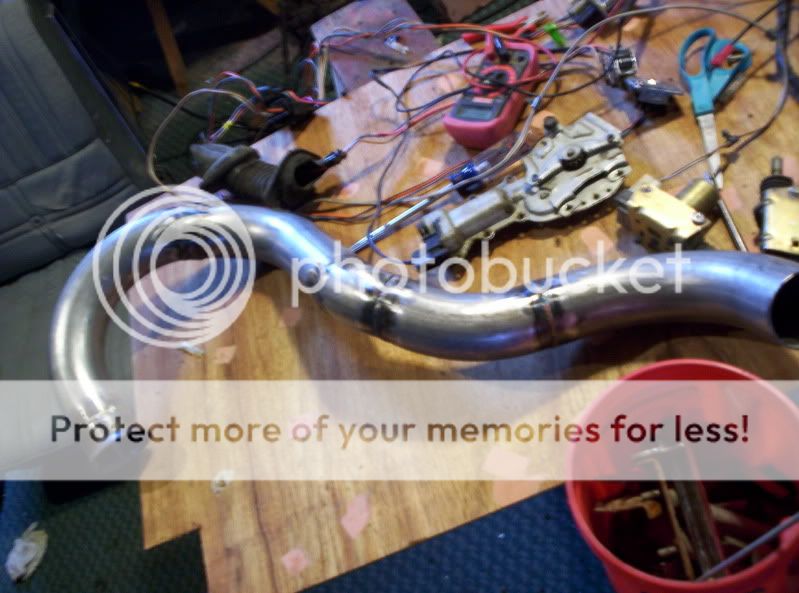

Overall dowpipes (83 is silver, 84/85 has braided top)

Close up of top section

Thanks,

OK, so after a year or so, I said to hell with ATR helping me out and took matters into my own hands. Last fall I picked up a used 84/85 ATR 2.5" pipe and figure I could get someone to weld a new top to it.

The ATR pipe is nice. It doesn't look bigger, but it's not double walled like the stock DP and is much bigger internally. It bolts the the stock 84/85 elbow, which uses the same donut gasket as our cars. That got me thinking.

Today I cut a section of the pipe out in the middle. If you bolt the bottom to the converter and the top to the turbo (using a 3-bolt flange instead of the 84/85 2-bolt flange) they come real close to meeting. I then connected them with so cheesy flex pipe and it fits. Actually the flex joint doesn't look bad and once I get some decent clamps on it, it will look good.

The ATR is pipe not too expensive. I think they are $135 new and I paid $50 for a good-used. A cut off wheel, a flex pipe and some clamps is all that is needed. Also, you either need to get the right 3-bolt flange or cut it off the stock pipe. Best part is that it's a DIY job - no exhaust shop needed.

Getting the stock pipe out is work. I had to removed the crossover and passenger side manfold. AC comporessor might get in the way if you have one.