Chevman2448

Member

- Joined

- Nov 15, 2013

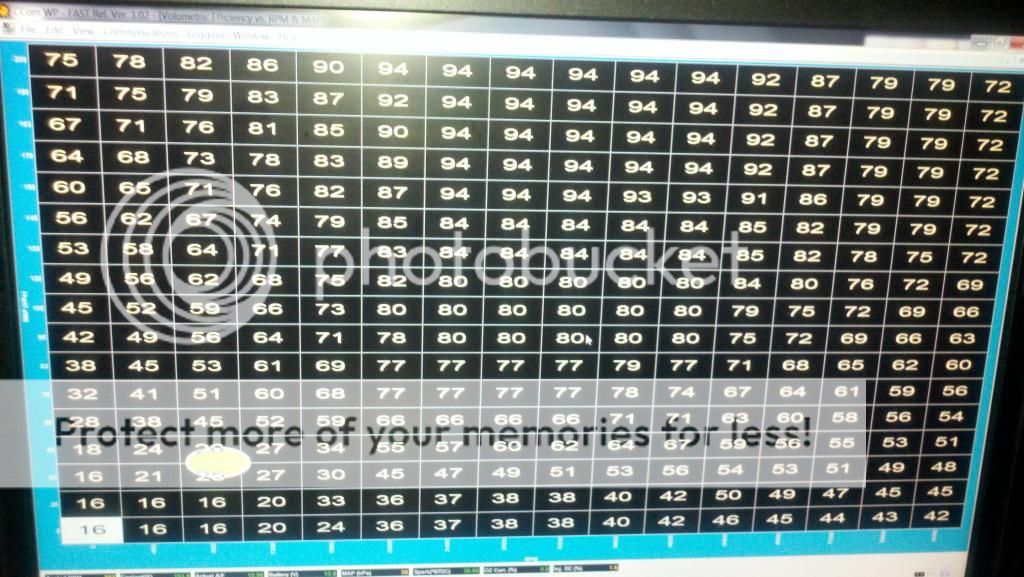

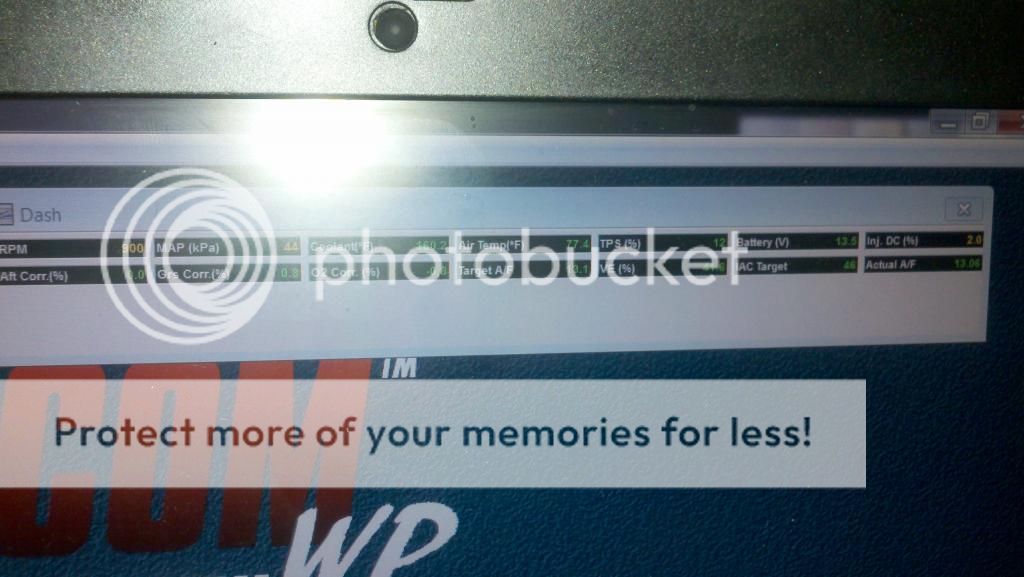

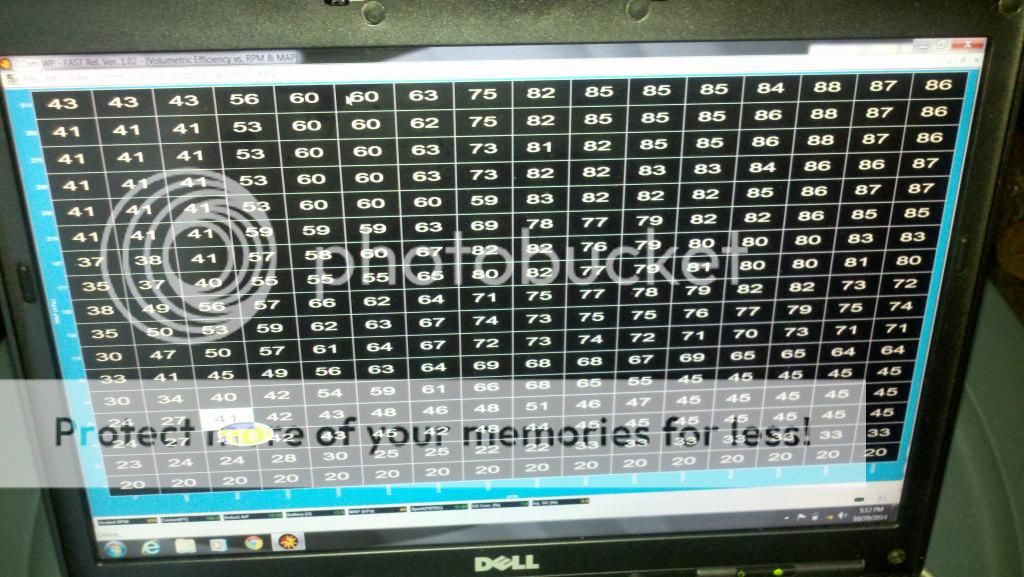

So if I understand you correctly....My INJ DC was so high because that is what it took to run the engine at those VE tables. But now that I dropped the INJ DC the VE tables all have to be increased 30%? Am I going to have to go through the entire VE table and increase all of the numbers in the table just as I did in the idle circuit?

Also Im not seeing a file in the C-Com programming for the stage 2 program you mentioned earlier.

Also Im not seeing a file in the C-Com programming for the stage 2 program you mentioned earlier.