Long story short---

Purchased the Racetronix DP set up with upgrade option to the Aeromtive 340 pumps (wanted to be the last set of pumps I would have to buy)...It does have the AN fittings on the sender (-8 feed, -6 retrun)

Installed Pumps (second pump on 15 lb hobbs switch) and currently running the stock feed line and filter with a -6 return line (from Erics post : http://www.turbotweak.com/forum/showthread.php?1968-Fuel-Return-Line-mods-for-bigger-pumps here on Turbo Tweak forum) . No issues with being able to control idle fuel pressure.....WOT FP is no issues 1:1 rise with boost...I'm at 21 lbs boost with 66+ lbs fuel pressure...80lb injectors

--66 lbs is measured at the fuel rail with a Caspers fuel pressure transducer on the power logger on the laptop log..

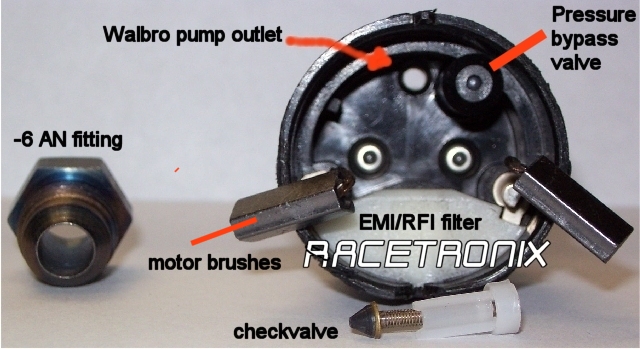

According to Aeromotive-I need to upgrade my feed line to a -10 preferably to handle the flow of both pumps when they are both on.....According to their tech I'm risking the internal pump bypass being activated (100psi setting) by having such a restrictive feedline and could damage the pumps over time...

He said I should but a guage on the line out of the sending unti feed before the filter and see what kind of pressure its at...He thinks Im probably close or over the 100psi bypass of the pump..

any thoughts from the group??

I'm looking into changing the feed line now and was wondering if a -6 feed line would be adequate or do i need to go -8 or even -10???

I can do a -6 feed line (using same 16' line as my return which had the ends pre-installed) with all parts from Jegs pretty economically.....

anyone have simialr issues/concerns/opinions??

Also the tech said that the filter should be changed every 10 hrs of run time on E85...

Purchased the Racetronix DP set up with upgrade option to the Aeromtive 340 pumps (wanted to be the last set of pumps I would have to buy)...It does have the AN fittings on the sender (-8 feed, -6 retrun)

Installed Pumps (second pump on 15 lb hobbs switch) and currently running the stock feed line and filter with a -6 return line (from Erics post : http://www.turbotweak.com/forum/showthread.php?1968-Fuel-Return-Line-mods-for-bigger-pumps here on Turbo Tweak forum) . No issues with being able to control idle fuel pressure.....WOT FP is no issues 1:1 rise with boost...I'm at 21 lbs boost with 66+ lbs fuel pressure...80lb injectors

--66 lbs is measured at the fuel rail with a Caspers fuel pressure transducer on the power logger on the laptop log..

According to Aeromotive-I need to upgrade my feed line to a -10 preferably to handle the flow of both pumps when they are both on.....According to their tech I'm risking the internal pump bypass being activated (100psi setting) by having such a restrictive feedline and could damage the pumps over time...

He said I should but a guage on the line out of the sending unti feed before the filter and see what kind of pressure its at...He thinks Im probably close or over the 100psi bypass of the pump..

any thoughts from the group??

I'm looking into changing the feed line now and was wondering if a -6 feed line would be adequate or do i need to go -8 or even -10???

I can do a -6 feed line (using same 16' line as my return which had the ends pre-installed) with all parts from Jegs pretty economically.....

anyone have simialr issues/concerns/opinions??

Also the tech said that the filter should be changed every 10 hrs of run time on E85...