Multiple fuel pumps

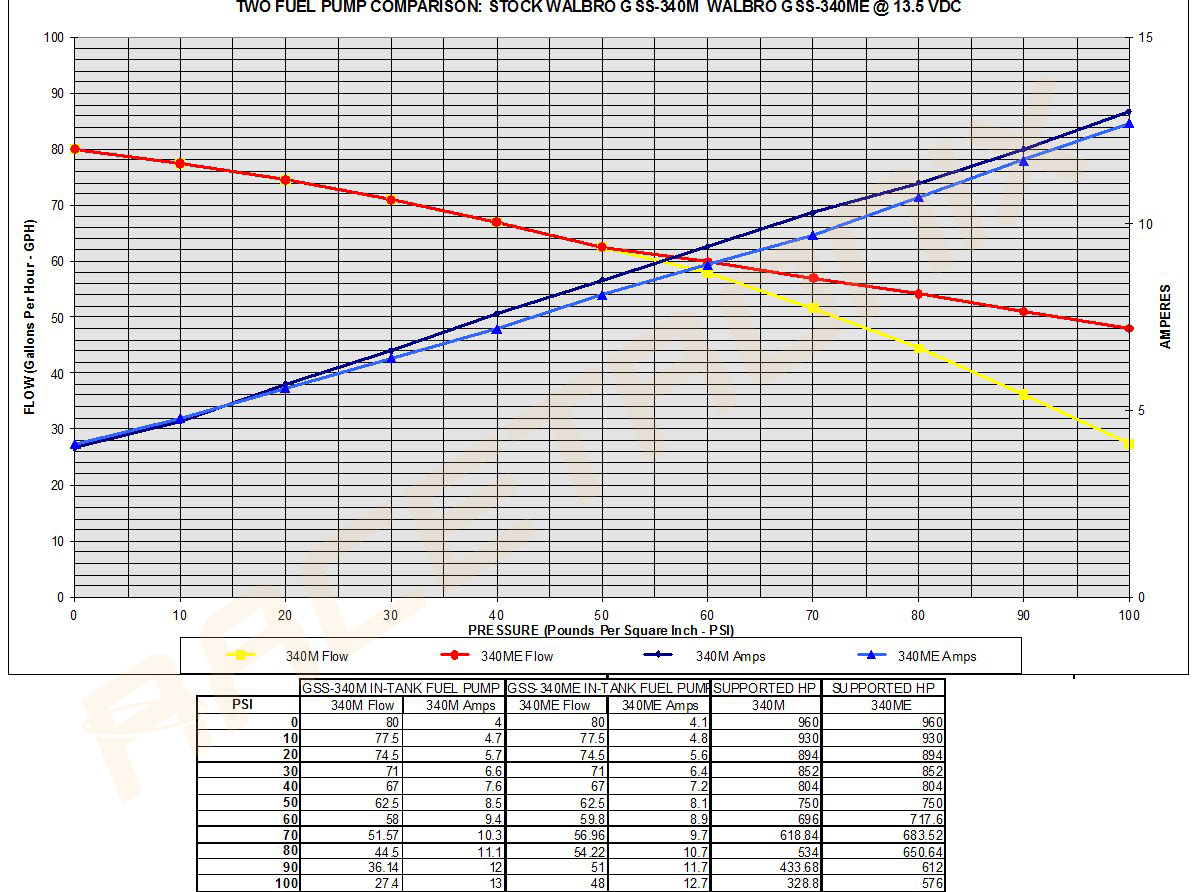

You can get a spool of 12 ga stranded copper wire for pretty cheap just about anywhere. 12 ga wire for a power lead is so close to as good as 10 ga that the voltage drop in 100 ft is only a nominal difference. 12 ga will use common spade connectors, and is much easier to work with. Radio Shak has 30 amp automotive relays for cheap. You can make a hot wire kit very inexpensively, compared to what you have to pay from a vendor. The Radio Shak relays are not weather proof, so they have to be placed under the hood instead of how the aftermarket (Weather Proof, Packard style) relays in the commercial kits are located, under the rear of the car. Trigger the pump relay with the grey wire with the (normally not used) black connector just behind the alternator. There are 2 open connectors in this area the other one is a double white wire with a green plastic connector. That is the tach lead. With the low cost in mind, it makes sense to run 2 separate power "Hot Wires" one for each pump. Don't forget to complete the circuit with the heavy ga wire for the neg side, or ground. The car body is the ground, not the frame. The tank body is the ground for the in-tank pump, and can be clamped at the flange but not drilled. The small ga wire running out from the sender will be over whelmed if you dont set up additional grounding for the intank pump, when using a hot wire there. The tank body should be connected to the car body with the same size wire that is used for the power feed. The external pump should be grounded to the car body. The Bosch pump that some of us ran as a second (in Line), worked well and lasted. It is a very cost and labor effective way to increase the fuel delivery at higher PSI. This is the real trick, since fuel flow drops off at higher pressure with all pumps. Some more than others. The dual, in-line (in series) will address this better than the parralel set-up. Keep in mind that running 2 pumps, (either set-up) will have it's own set of concerns, over running a single proper capacity pump. A single pump properly sized to supply enough fuel for good power will likely require some additional modification to the system, and therefore extra cost and work.