dragway

Member

- Joined

- Nov 6, 2011

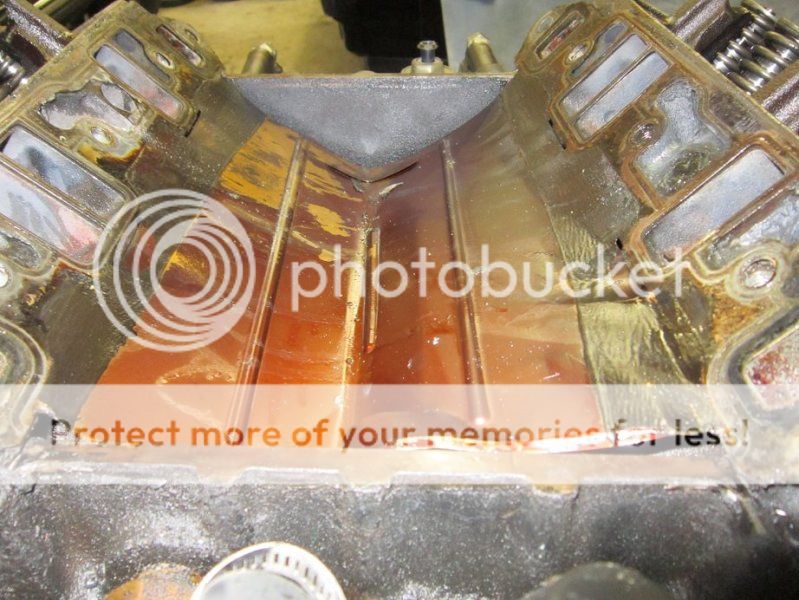

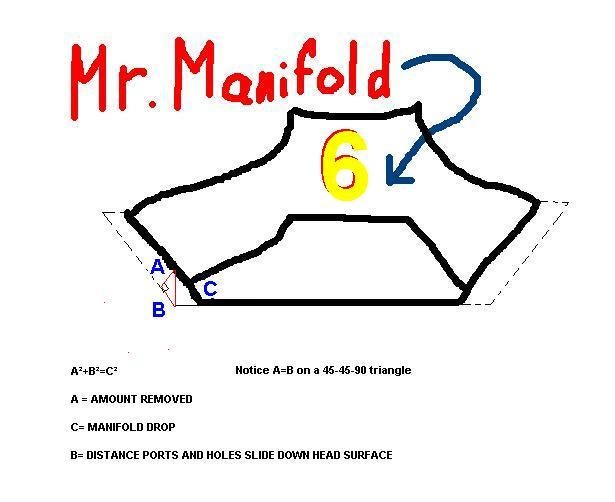

After taking engine out do to blown headgasket when I took off throttlebody and dog house was coated on inside with oil took lower intake off and found that it didn't have the pan style gasket and Pcv was sucking up oil would that hurt performance and could it cause detonation ?