John Larkin

Sublime Master of Turbology

- Joined

- May 25, 2001

I bought the smooth bottom one, see the part number on the box

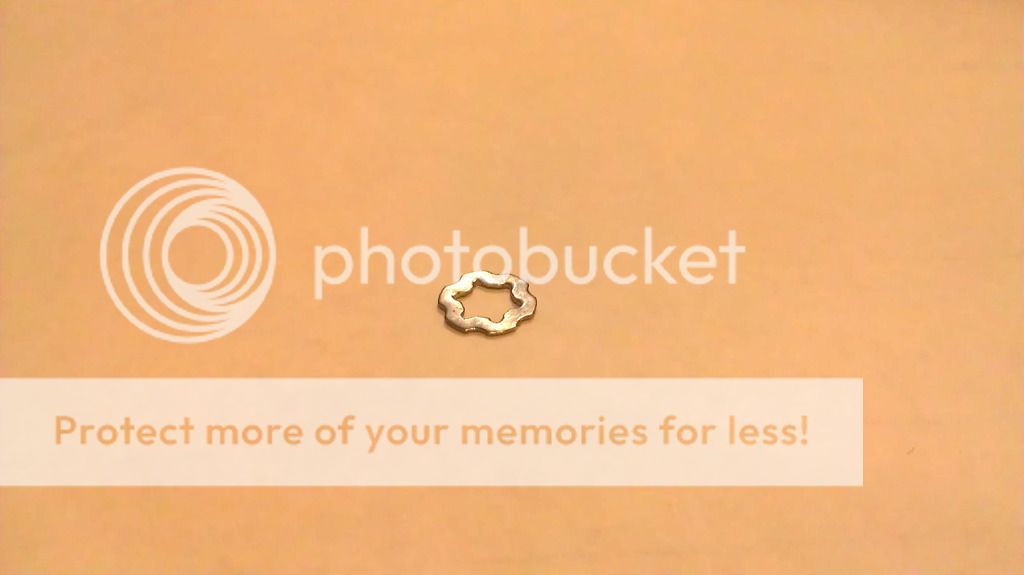

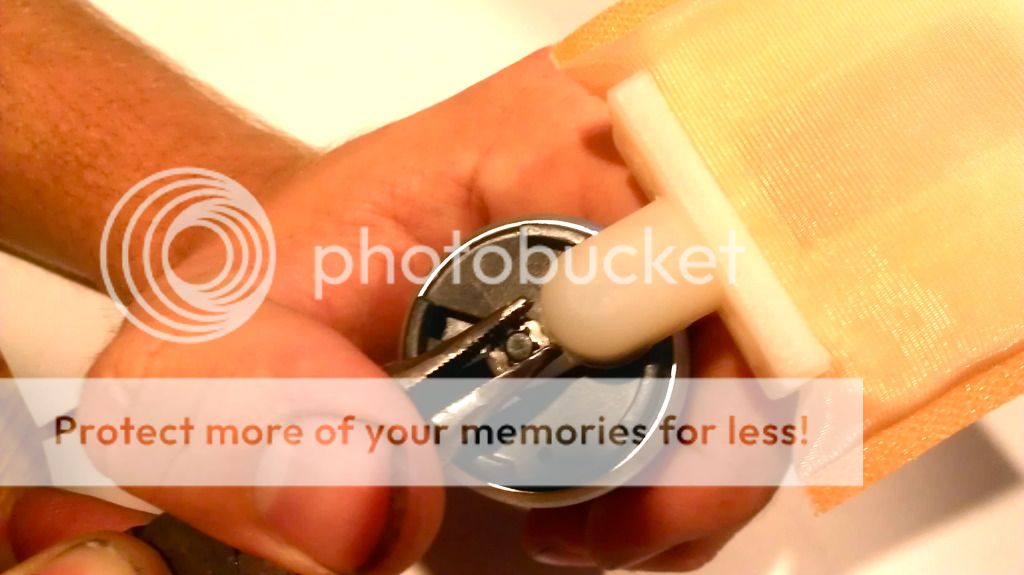

. It fits fine in the hanger, no bumps protruding and you can rotate the pump pretty much to your heart's content. The sock is very stiff and I ended up having to rotate the pump from the photo more toward the return tube so I could get it in the tank. The sock will bend a bit but not much. And it is a pain to get that little star friction washer over the pin to hold the sock in place. Takes dexterity and patience and a couple of small screwdrivers to press it on with. I had some connectors in my electrical box I had scavenged from some wiring I obtained and was able to refit the old Walbro adapter plug onto the new DW connector. So everything works, pump is reasonably quiet (I tested it before installing). Now to get some fuel in the car and see what happens.

. It fits fine in the hanger, no bumps protruding and you can rotate the pump pretty much to your heart's content. The sock is very stiff and I ended up having to rotate the pump from the photo more toward the return tube so I could get it in the tank. The sock will bend a bit but not much. And it is a pain to get that little star friction washer over the pin to hold the sock in place. Takes dexterity and patience and a couple of small screwdrivers to press it on with. I had some connectors in my electrical box I had scavenged from some wiring I obtained and was able to refit the old Walbro adapter plug onto the new DW connector. So everything works, pump is reasonably quiet (I tested it before installing). Now to get some fuel in the car and see what happens.