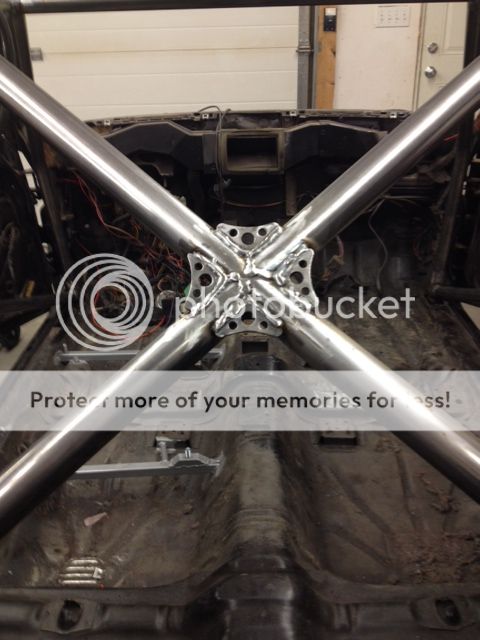

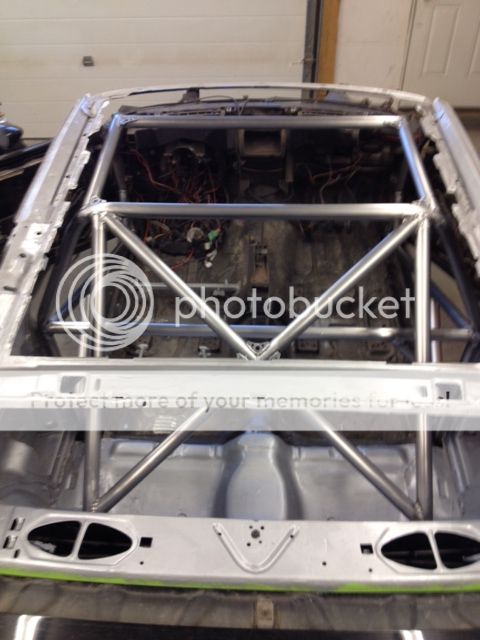

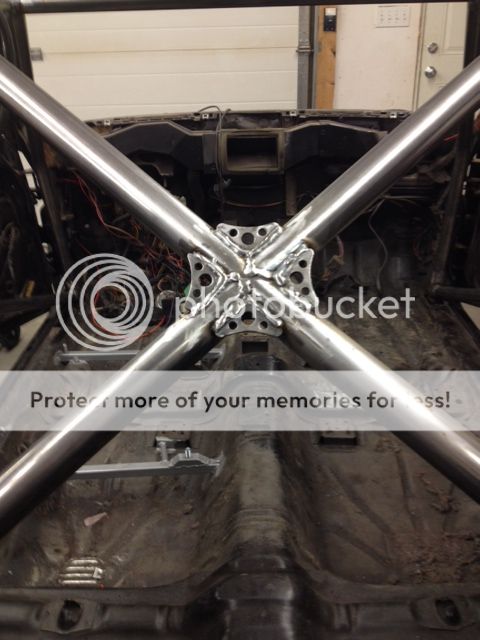

I finished installing my 10 point cage today. Now I have to weld up the floor and paint. This is the 10 point pre-bent cage with an optional x-bar and door bar kit installed. I was lucky enough that i was going to be replacing my roof skin anyway so no roof made it a little easier.

The quality of the cage is good, it will be very tight to the roof of the car. 6 points were welded to the frame, and its a mild steel cage. I added gussets and a few extra bars just for my own piece of mind. On to the pics!

The quality of the cage is good, it will be very tight to the roof of the car. 6 points were welded to the frame, and its a mild steel cage. I added gussets and a few extra bars just for my own piece of mind. On to the pics!