Greetings.. While not a GN nor the same 3.8, my turbo 3800 gets coupled/compared to the original.

Always been a huge GN fan. Growing up as a kid, my neighbor (rip) owned a GNX. Yes, not a knock

off, the real deal.

Anyways... keeping with the spirit of the 3.8 V6's and not having a GN, little over a year ago, started

a turbo grand prix project with my friend Sean. We had been drag racing his GTP for years, but

decided to pretty much retire it, and we both went in on this project. Picked up a $1000 beater

to start with.

Neither one of us are mechanics or anything. We never had

a turbo car or worked on one until started on this. So a new realm and a lot of learning.

Engine is a stock 200k + short block. Just had new bolts, bearings, rings put in.

Local heads, a turbo cam, and double roller. Nothing to crazy.

Using a mutt T67 turbo.

I had my doubts on the setup, but ended up smiling from ear to ear the first test drive

I got to do under boost. I knew instantly, this is gonna be fun.

We did a full year of racing this year with a lot of passes. Only things to break

was an intercooler bracket and a belt. Pretty good I'd say.

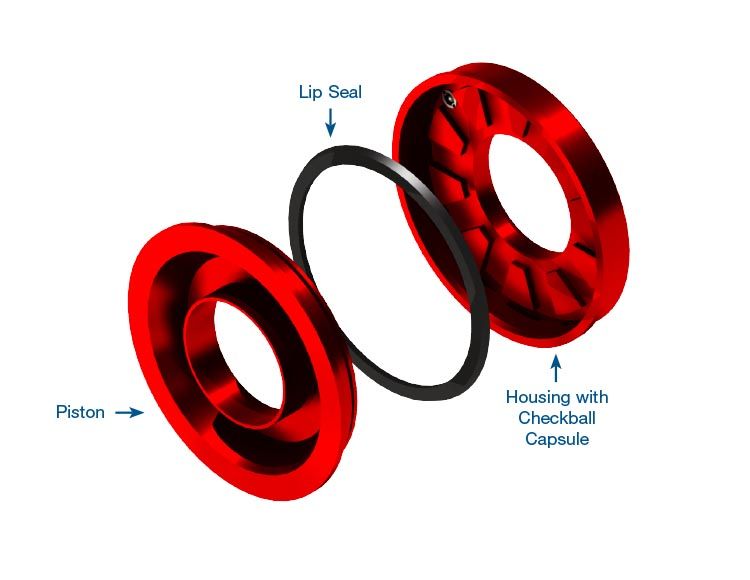

Transmission, while a lot of work and $ tossed into it, the converter slip was hurting

the top end. This is getting addressed over the winter. PI multi disc locking converter,

transbrake and two step... and some other goodies. Should proove interesting on the

learning curve to launch it. Just started to get under control too.

Best pass being a 10.41@132 with a 1.56 60' at 21 psi. Car is around 3000lbs

without a driver.

Not to shabby I'd like to think. 19-22 psi the car did not get much if any faster.

The converter slip just gets worse with more boost. After the new trans setup,

hopes are that we can max out the little T67 around 25-26 psi and get all the

power to the ground.

Only been to dyno once. This was at Cincy Speed. With a factory style fuel system,

with a racetronix pump. We started to go lean at 17psi, but managed 529whp.

GM High Tech Performance picked up on the dyno videos from Cincy Speed and

had them on their facebook page. Thought that was kinda neat.

Our buddy PRJ rewired the whole car for us. Removing everything that wasn't needed.

Jesus was there a lot of wires. Fuse box moved to dash under the air bag panel.

PCM located in glove box. Battery under front bumper.

He also did our full fuel cell and supply setup. Came out pretty good. Anyways Ill toss up some pics

of when the setup was in progress..

A lot of work from different people went into this. A bit of custom work. A lot of parts

we had to make up our selves.

Car when we picked it up from PRJ. Engine bay cleaned up very well moving all the

crap out of the way. Started and ran just fine. Some of his progress pics.

Cage work by Rogue Race Cars. Was their first FWD drag car job.

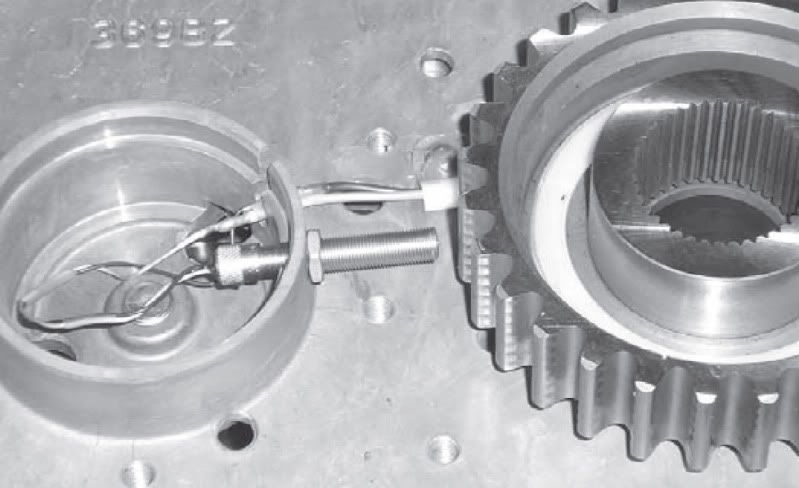

Front coil overs that PRJ gave us designs, and Sean machined the parts and came up

with these. This is a really nice setup, as the shocks can be pulled out and replace. Instead

of tossing the whole setup away like the ones available.

Aeromotive Eliminator fuel setup. Ya I know bad choice. But hoping we have issues

under control finally with it

Intercooler pipes we made and had tig welded for us. Only four couplers total. Less chance

of blowing crap apart. Took a few hours to do, but I think came out nicely.

Upper intake is off the 3800 fbody. Using a stock L67 throttle body adapted

to fit (drill and tap a hole is all).

Test fitting parts here. The cross over and downpipe I bought from a guy on a forum,

But they ended up not fitting worth a crap, and we ended up hacking it all up and redoing

it all. Kinda stunk, as wasted $ there. But it is what its....

Final engine bay shot of pretty much what it looks like currently.

May change up a little bit over the winter but not much.

Our last day at the track video...

Rest @ http://www.youtube.com/user/jdredd34

Sorry for the long book here, but thought maybe a few would find it interesting..

Come to find out a few guys at the track with GN's tend to have 3800 powered

beater cars and get a kick out of this turd.

Plans for 2014 is try and get into the 9's with the current engine/turbo setup.

The new transmission setup should hopefully let us get there.

So anyways, hope ya guys like it and that I didn't waste your time.

Always been a huge GN fan. Growing up as a kid, my neighbor (rip) owned a GNX. Yes, not a knock

off, the real deal.

Anyways... keeping with the spirit of the 3.8 V6's and not having a GN, little over a year ago, started

a turbo grand prix project with my friend Sean. We had been drag racing his GTP for years, but

decided to pretty much retire it, and we both went in on this project. Picked up a $1000 beater

to start with.

Neither one of us are mechanics or anything. We never had

a turbo car or worked on one until started on this. So a new realm and a lot of learning.

Engine is a stock 200k + short block. Just had new bolts, bearings, rings put in.

Local heads, a turbo cam, and double roller. Nothing to crazy.

Using a mutt T67 turbo.

I had my doubts on the setup, but ended up smiling from ear to ear the first test drive

I got to do under boost. I knew instantly, this is gonna be fun.

We did a full year of racing this year with a lot of passes. Only things to break

was an intercooler bracket and a belt. Pretty good I'd say.

Transmission, while a lot of work and $ tossed into it, the converter slip was hurting

the top end. This is getting addressed over the winter. PI multi disc locking converter,

transbrake and two step... and some other goodies. Should proove interesting on the

learning curve to launch it. Just started to get under control too.

Best pass being a 10.41@132 with a 1.56 60' at 21 psi. Car is around 3000lbs

without a driver.

Not to shabby I'd like to think. 19-22 psi the car did not get much if any faster.

The converter slip just gets worse with more boost. After the new trans setup,

hopes are that we can max out the little T67 around 25-26 psi and get all the

power to the ground.

Only been to dyno once. This was at Cincy Speed. With a factory style fuel system,

with a racetronix pump. We started to go lean at 17psi, but managed 529whp.

GM High Tech Performance picked up on the dyno videos from Cincy Speed and

had them on their facebook page. Thought that was kinda neat.

Our buddy PRJ rewired the whole car for us. Removing everything that wasn't needed.

Jesus was there a lot of wires. Fuse box moved to dash under the air bag panel.

PCM located in glove box. Battery under front bumper.

He also did our full fuel cell and supply setup. Came out pretty good. Anyways Ill toss up some pics

of when the setup was in progress..

A lot of work from different people went into this. A bit of custom work. A lot of parts

we had to make up our selves.

Car when we picked it up from PRJ. Engine bay cleaned up very well moving all the

crap out of the way. Started and ran just fine. Some of his progress pics.

Cage work by Rogue Race Cars. Was their first FWD drag car job.

Front coil overs that PRJ gave us designs, and Sean machined the parts and came up

with these. This is a really nice setup, as the shocks can be pulled out and replace. Instead

of tossing the whole setup away like the ones available.

Aeromotive Eliminator fuel setup. Ya I know bad choice. But hoping we have issues

under control finally with it

Intercooler pipes we made and had tig welded for us. Only four couplers total. Less chance

of blowing crap apart. Took a few hours to do, but I think came out nicely.

Upper intake is off the 3800 fbody. Using a stock L67 throttle body adapted

to fit (drill and tap a hole is all).

Test fitting parts here. The cross over and downpipe I bought from a guy on a forum,

But they ended up not fitting worth a crap, and we ended up hacking it all up and redoing

it all. Kinda stunk, as wasted $ there. But it is what its....

Final engine bay shot of pretty much what it looks like currently.

May change up a little bit over the winter but not much.

Our last day at the track video...

Rest @ http://www.youtube.com/user/jdredd34

Sorry for the long book here, but thought maybe a few would find it interesting..

Come to find out a few guys at the track with GN's tend to have 3800 powered

beater cars and get a kick out of this turd.

Plans for 2014 is try and get into the 9's with the current engine/turbo setup.

The new transmission setup should hopefully let us get there.

So anyways, hope ya guys like it and that I didn't waste your time.