DougsfastZ

4.1

- Joined

- Jan 30, 2004

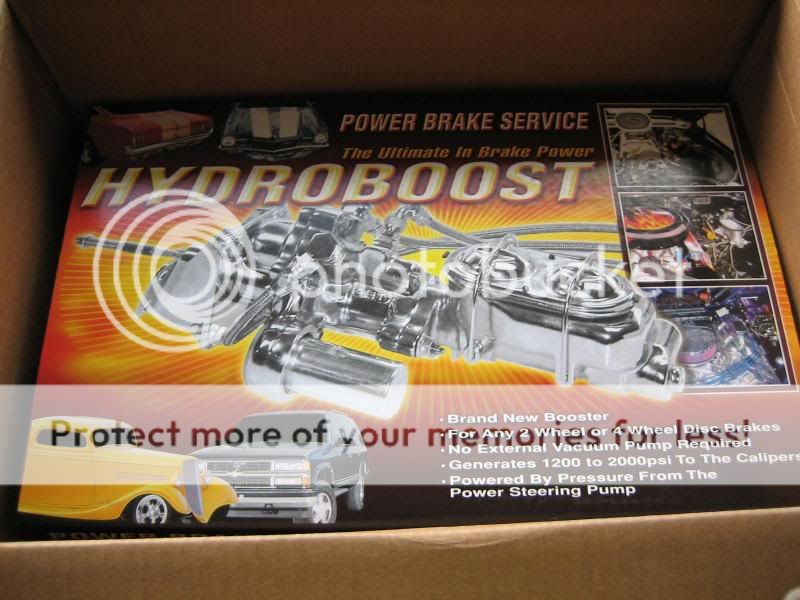

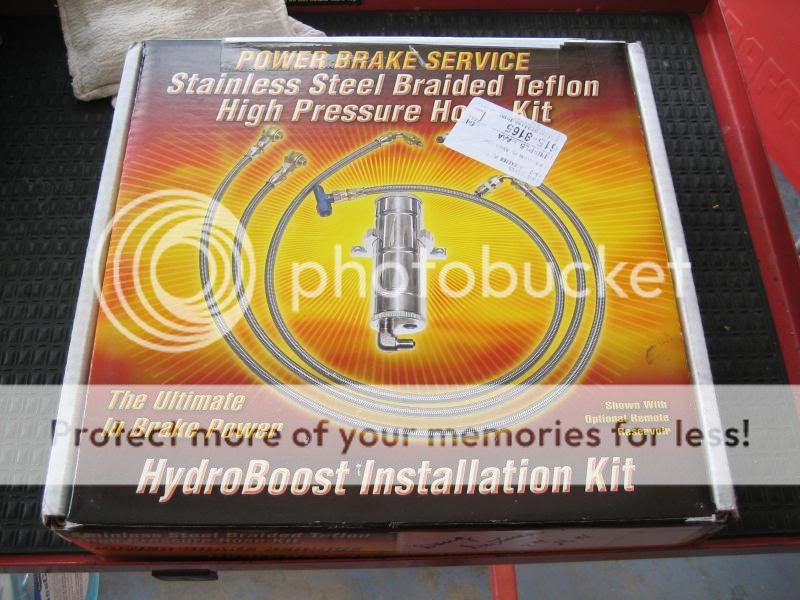

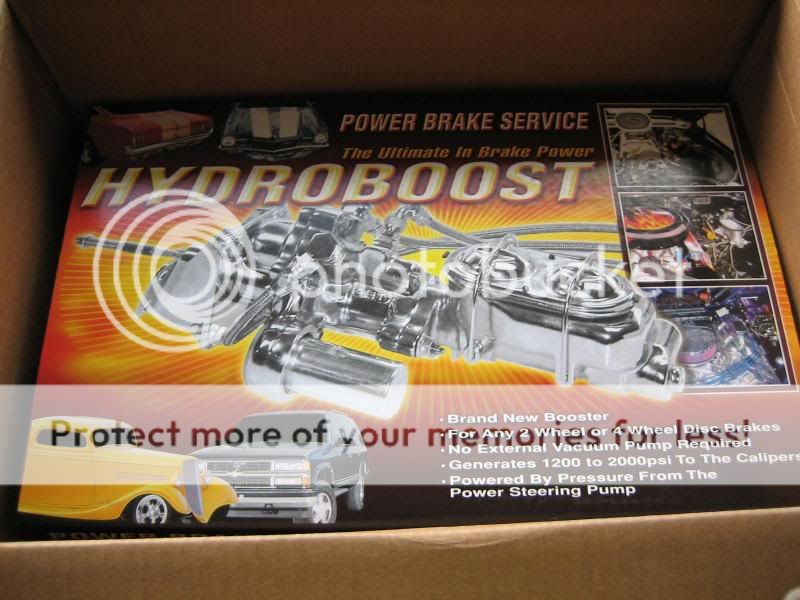

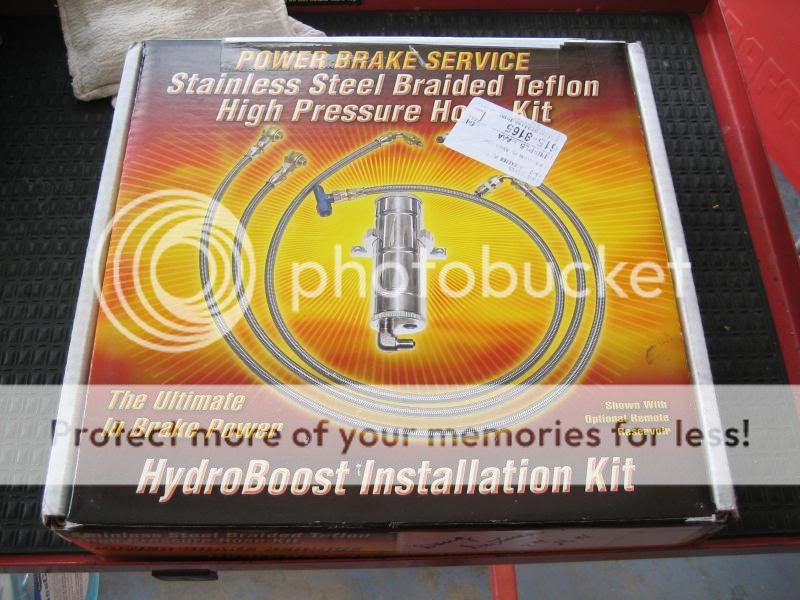

This write up is based on the installation of a hydroboost braking system installed into my 1987 Grand National. I bought the kit through Bob at Power Brake Services.com I ordered the standard cast Hydroboost, standard master cylinder, and upgraded to all stainless steal lines. The hydroboost system in this write up is replacing a stock powermaster system from GM.

I'll begin by showing how the components were shipped. The system came in two boxes, one for the Hydroboost and master cylinder, the other for the lines and fittings. It took about 2 weeks to recieve the H/B and MC, and 3 weeks to receive the lines after I ordered it. Everything was packaged very well and was not damaged in any fashion.

On to the install, the first thing to always remember is have a fully stocked fridge with your favorite beverages!

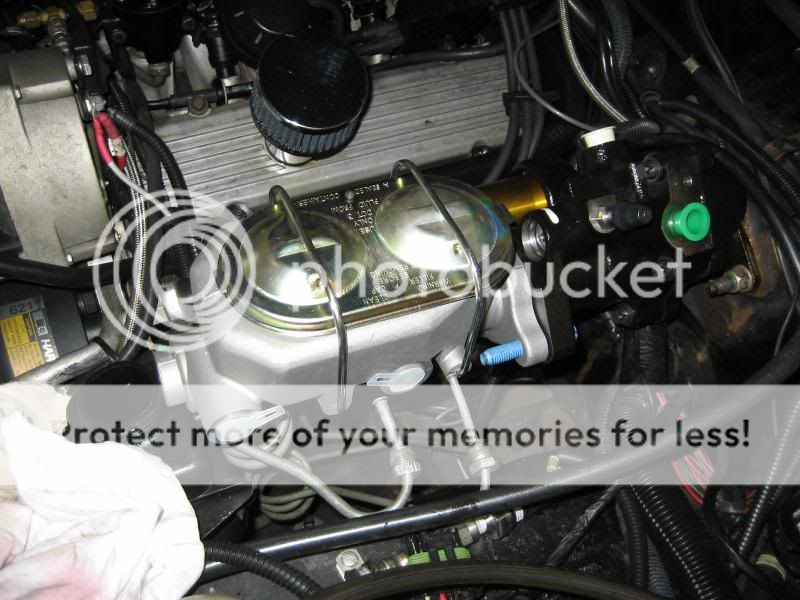

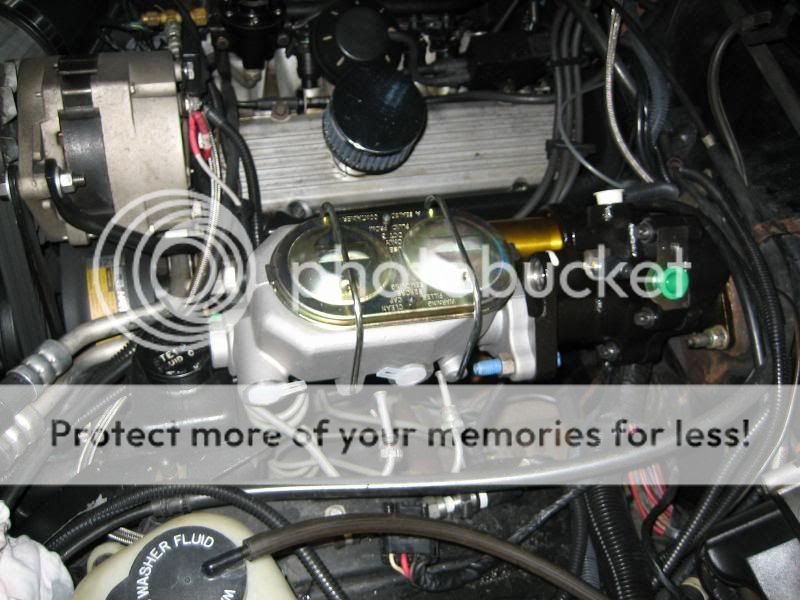

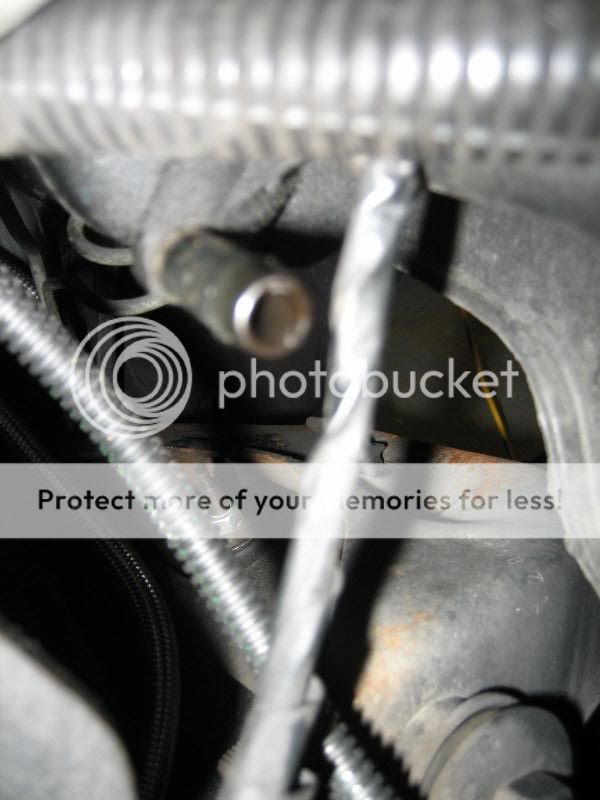

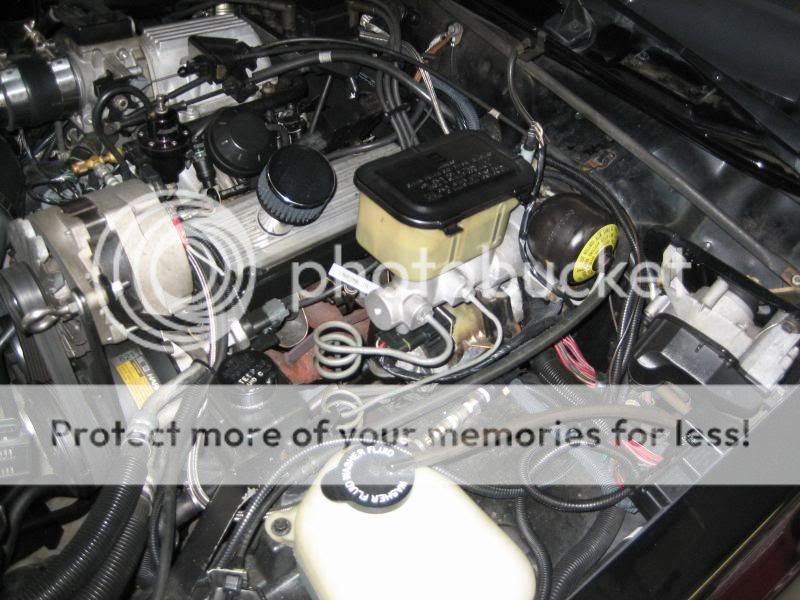

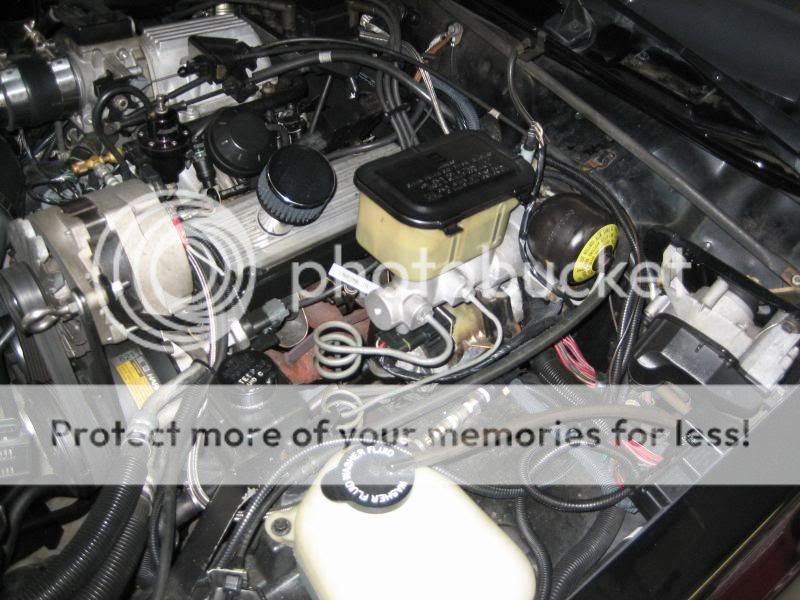

Here is a picture of the powermaster setup that came with the car from the factory.

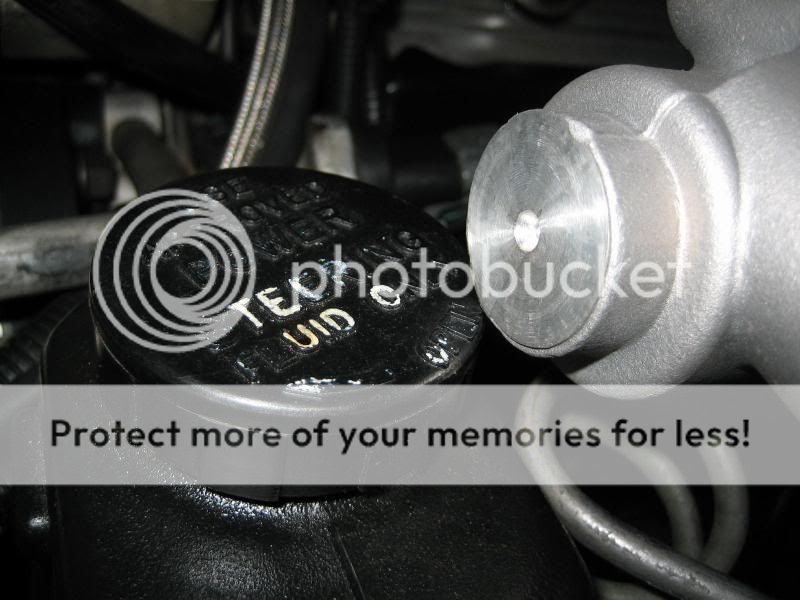

I proceeded to drain all brake and power steering fluid from their prospective reservoirs. I used an old turkey baster, which took some time, but got the job done.

Continue

I'll begin by showing how the components were shipped. The system came in two boxes, one for the Hydroboost and master cylinder, the other for the lines and fittings. It took about 2 weeks to recieve the H/B and MC, and 3 weeks to receive the lines after I ordered it. Everything was packaged very well and was not damaged in any fashion.

On to the install, the first thing to always remember is have a fully stocked fridge with your favorite beverages!

Here is a picture of the powermaster setup that came with the car from the factory.

I proceeded to drain all brake and power steering fluid from their prospective reservoirs. I used an old turkey baster, which took some time, but got the job done.

Continue