salvageV6

Daily Driver

- Joined

- May 25, 2001

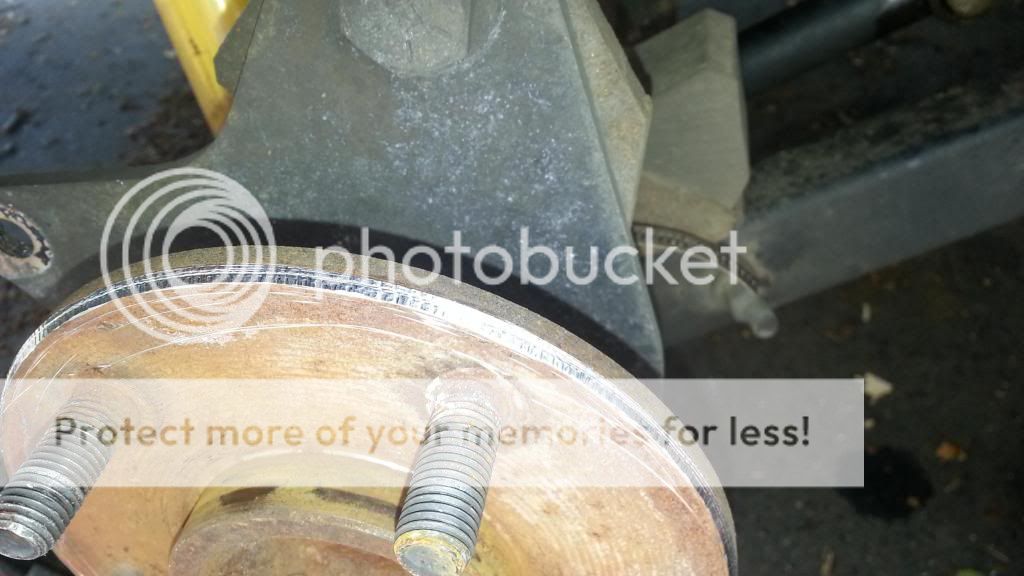

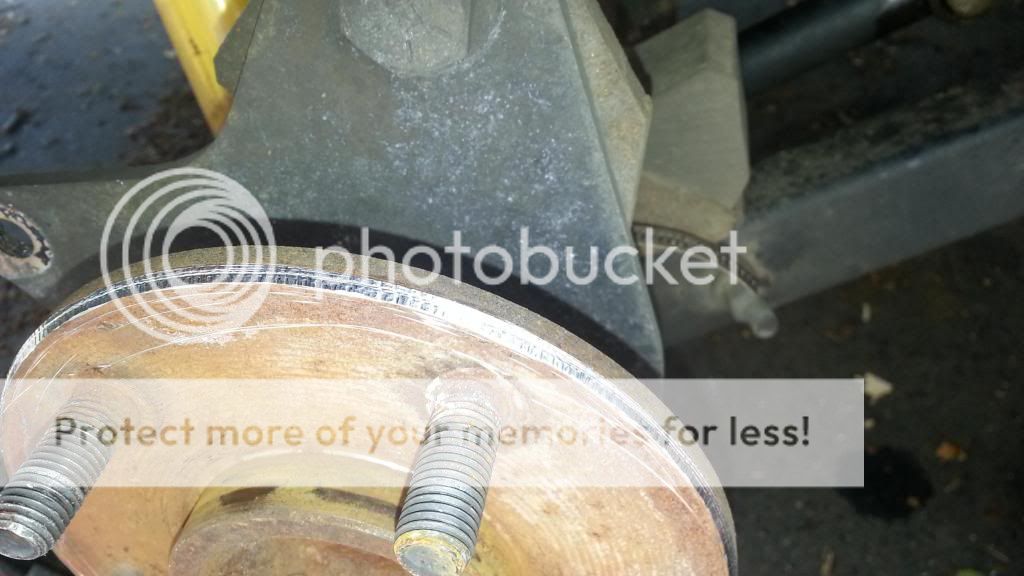

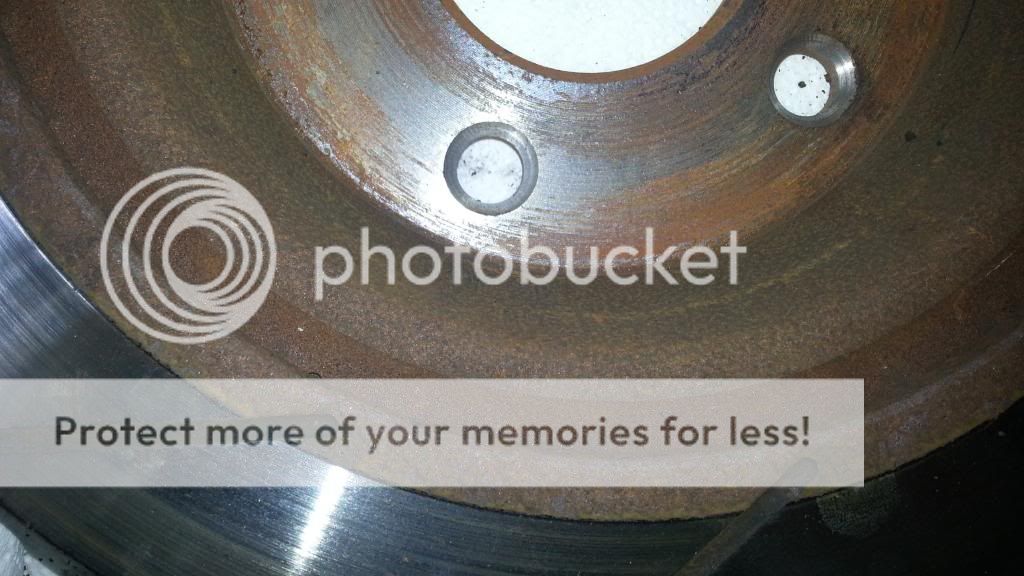

Well it's good to know you can turn the axle flanges down a bit while still on the car.

Had to do it to fit aftermarket EBC stock replacement gray iron rotors, with the Baer rear brakes, not every Corvette rotor fits these brakes in the Buick application I guess.

EBC's were about half the price of the Baer rotors.

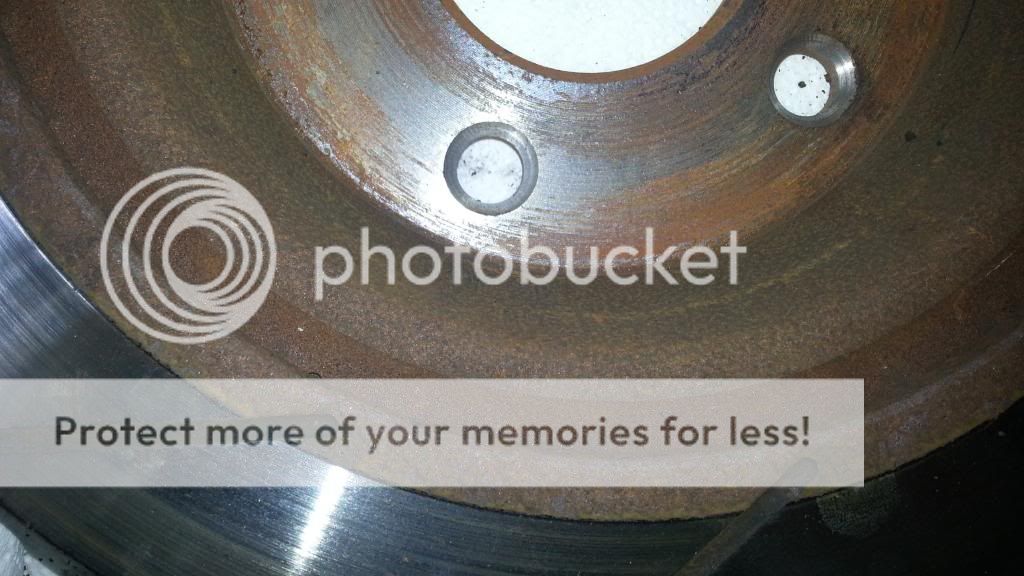

Only needed a 1/8" clearance and a 45 degree angle cut, and it took about 5 minutes a side, this pic. is the first cut after about a minute when I stopped to test clearance.

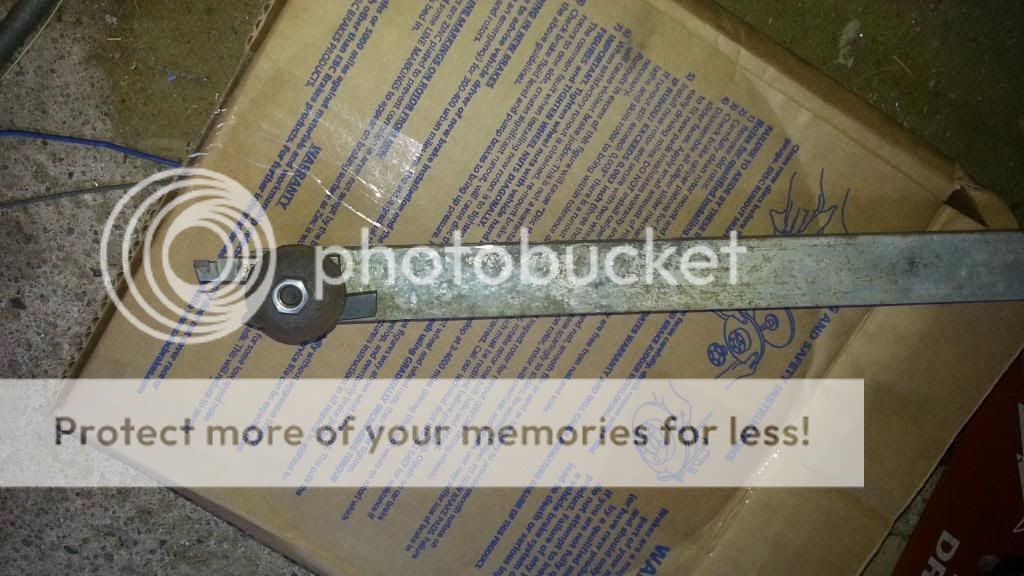

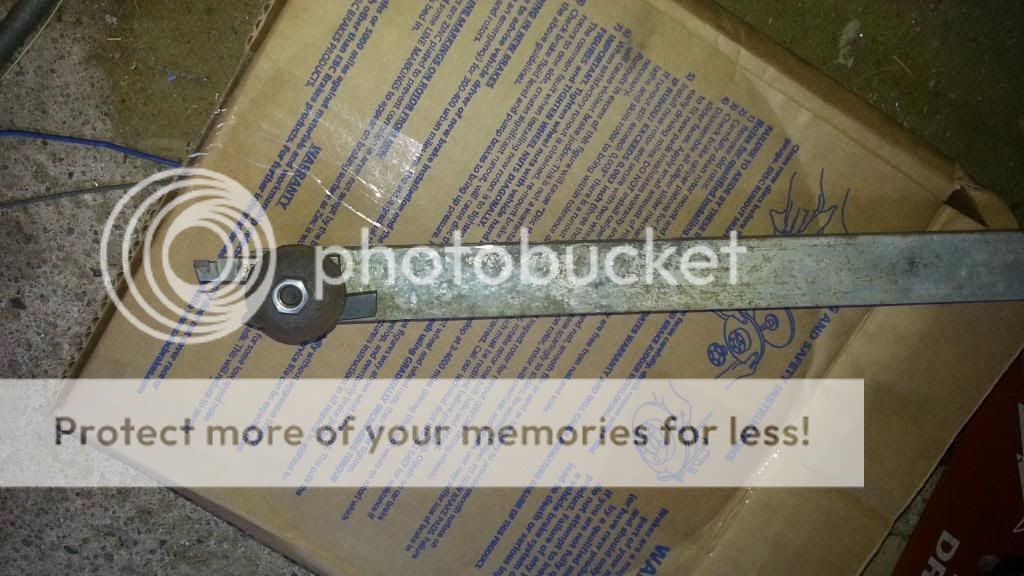

Carbide tool a must, on a stick.

Chestnut hardwood log for the fulcrum.

Didn't want to touch and weaken the rotor, every dimension but the "hat" interior clearance angle was exact to the Baer rotors, thicknesses, bolt patterns, etc.

Idle speed is all you need, and of course some bricks and jack stands.

With some time I think you could probably go all the way across the rotor and take off perhaps up to 1/4" if you needed or make a better tool jig and go right down to the studs.

Had to do it to fit aftermarket EBC stock replacement gray iron rotors, with the Baer rear brakes, not every Corvette rotor fits these brakes in the Buick application I guess.

EBC's were about half the price of the Baer rotors.

Only needed a 1/8" clearance and a 45 degree angle cut, and it took about 5 minutes a side, this pic. is the first cut after about a minute when I stopped to test clearance.

Carbide tool a must, on a stick.

Chestnut hardwood log for the fulcrum.

Didn't want to touch and weaken the rotor, every dimension but the "hat" interior clearance angle was exact to the Baer rotors, thicknesses, bolt patterns, etc.

Idle speed is all you need, and of course some bricks and jack stands.

With some time I think you could probably go all the way across the rotor and take off perhaps up to 1/4" if you needed or make a better tool jig and go right down to the studs.