toomanymodz

Well-Known Member

- Joined

- Oct 14, 2009

I conducted a leakdown test on my new engine and all cylinders are at 9%, except for one at 4% and one at 15%. When the boost is over 15psi the pressure builds and causes my turbo to leak (due to pressure prohibiting outflow of oil from drain), thus smoking out the exhaust.

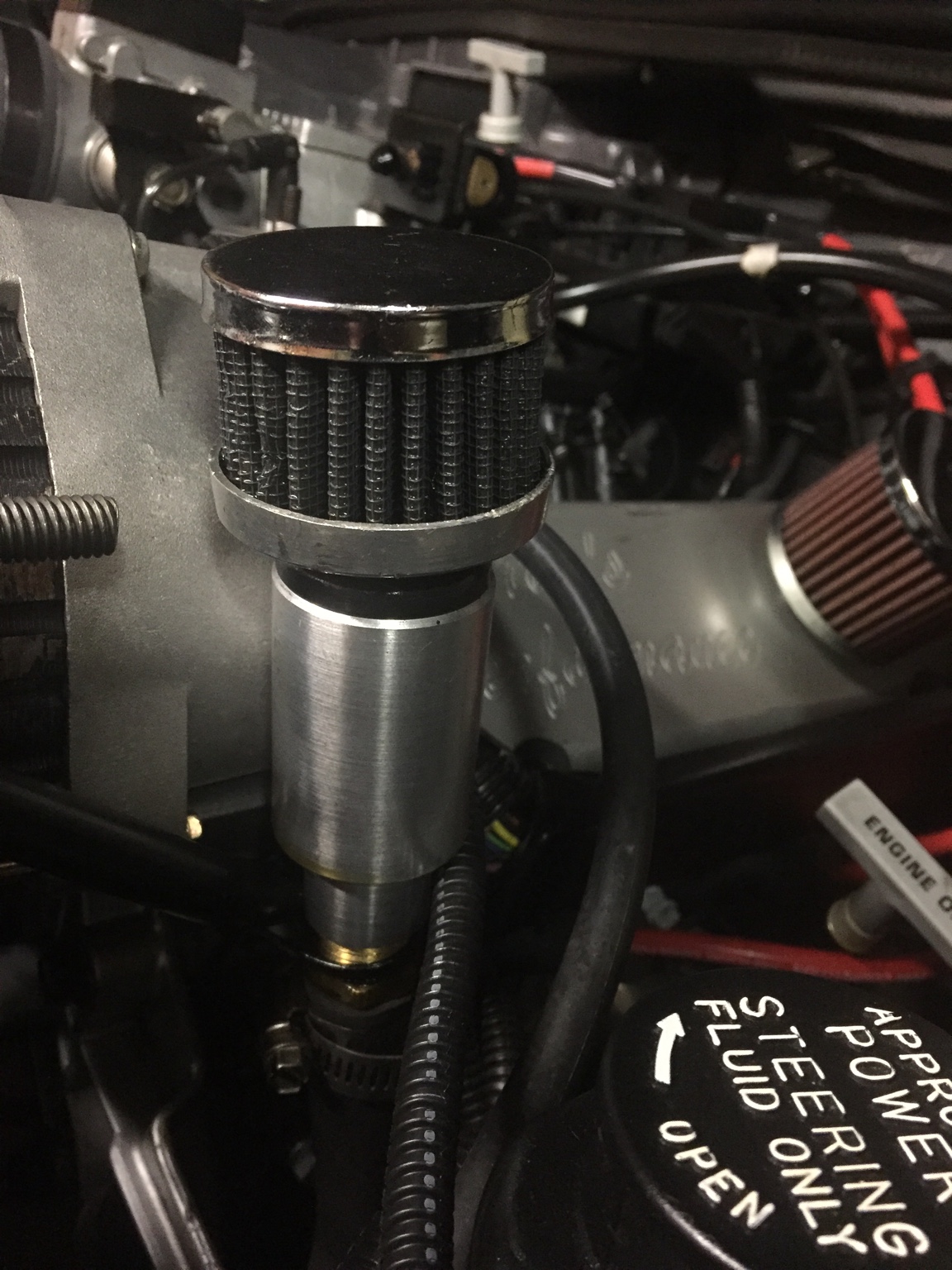

Instead of pulling the motor, are there techniques that have been tried such as large diameter or high-flow breathers, or vacuum pumps etc. I see many of the LS folks running the pumps and I'm sure it would help my 'pressure' situation.

Instead of pulling the motor, are there techniques that have been tried such as large diameter or high-flow breathers, or vacuum pumps etc. I see many of the LS folks running the pumps and I'm sure it would help my 'pressure' situation.