There seems to be alot of misinformation here.

First, the inlet of your turbo pulls more vaccum than that pump, I promise. If you don't believe me, measure it.

Second, a belt driven vacuum pump will not affect oil pressure. It will, however, suck the oil off the cylinder walls causing excess friction.

Theres nothing wrong with using the electric pump, but running your PCV into the compressor inlet is more effective. Norbs has a nice setup to illustrate what I'm talking about.

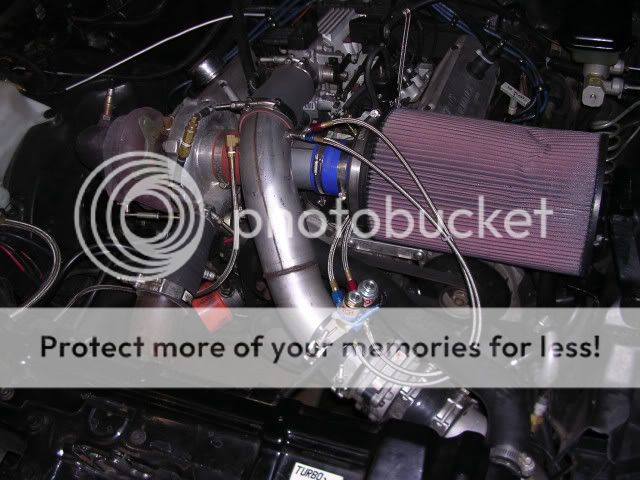

You mean like this?

If so, I hate to break it to you buddy, but it doesn't work.

I'm speaking from experience, not theory.

I really did not want to have to add the smog pump and that is why I tried what you THEORIZE works better. I even shaped the bung on the inside of the tube like the discharge tube in a carburetor venturi to maximize vacuum. Know what that looks like?

I think the enormous cloud of oil smoke and oil all over my engine bay were good indications that the amount of vacuum being pulled from there was not enough, and indeed was LESS effective than just running breathers.

"First, the inlet of your turbo pulls more vaccum than that pump, I promise. If you don't believe me, measure it. "

I think you are forgetting about the huge vacuum leak in that system called THE AIR FILTER. Certainly if I plugged the air filter, then I would be pulling nothing but crankcase air but then the car wouldn't run.

The differential pressure you suggest using is only whatever you get from the impeller wheel to the air filter opening, and that is not a whole lot in a properly designed turbocharger inlet. If there is, then please explain why my original system did not work. I'm open ears.

Bear in mind that I still have my pump exhaust to this bung to take advantage of whatever delta p might exist in that pipe but I can assure you, it's not a lot. The gain is in the airflow over a properly shaped tube entry to take advantage of the low pressure region behind a slash cut tube opening.

In NA apps if you are seeing even 1" HG of static manifold vacuum at wot then that means you are choking the engine. From the impeller to the airfilter is much like a plenum in a naturally aspirated application. If you are seeing even 1" Hg then you need to look at redesigning your turbo intake setup.Turbos are very inefficient vacuum generators.