77 cruiser

Well-Known Member

- Joined

- May 24, 2001

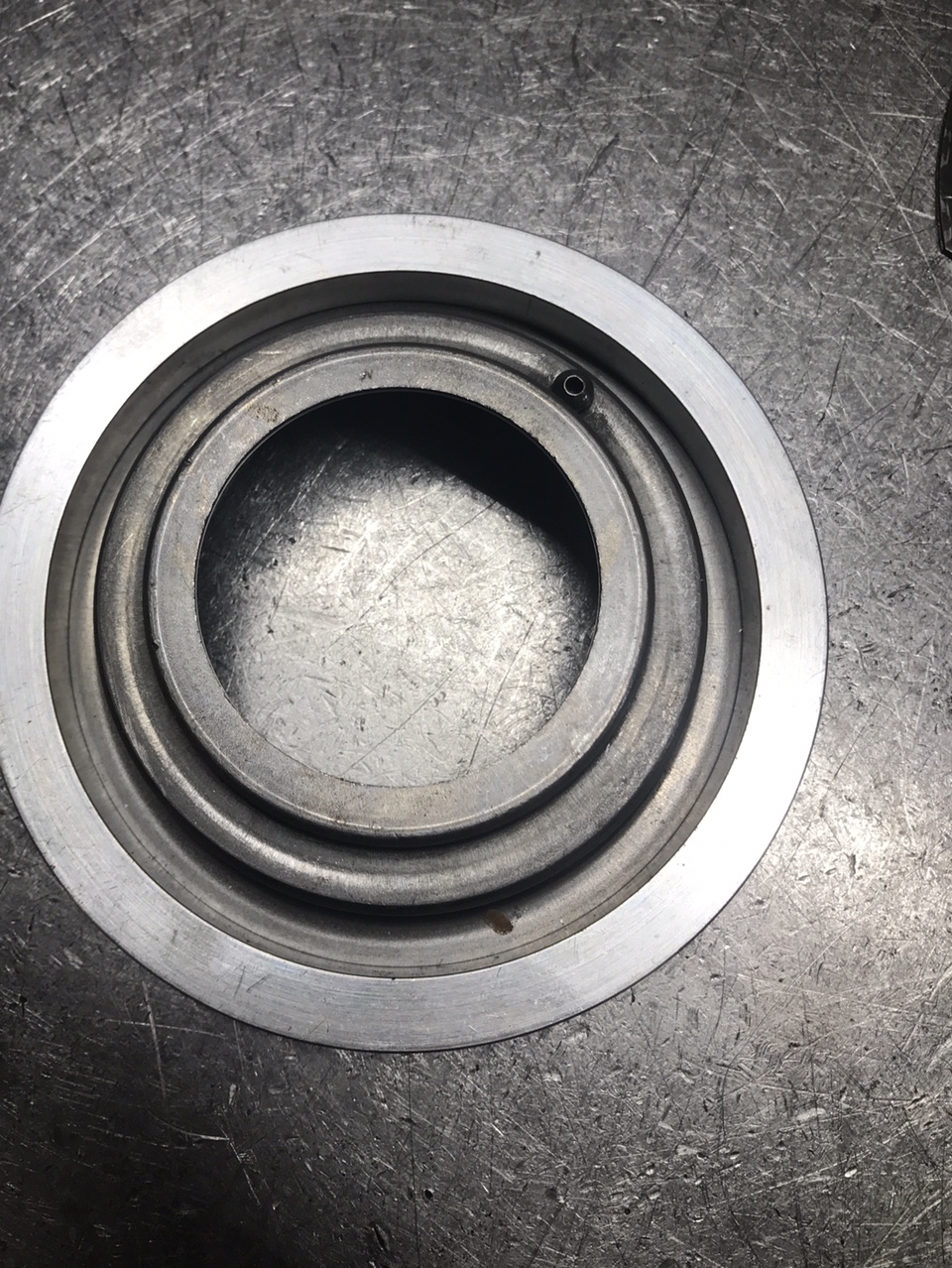

I tore my trans down to take a look cause I had it out due to converter issues.

Found the directs were burned & steels hot spotted.

Would a slight bind on the 2-3 cause it?

Don't ask what the press. was, I never checked, thought they would be good they were 270 with the same pump before.

Didn't have the 3-2 valve blocked then I do now.

Found the directs were burned & steels hot spotted.

Would a slight bind on the 2-3 cause it?

Don't ask what the press. was, I never checked, thought they would be good they were 270 with the same pump before.

Didn't have the 3-2 valve blocked then I do now.