I finally got around to taking the heads off today.

Found some exhaust leaks that had to be minor.

This header flange is out of round.

Crank seal leaking with 1200 miles on it. 2nd one. My first build shot a head gasket but didn't milkshake the motor but there was moisture. That created a rust ring on my balancer after it sat for a while. I cleaned up the balancer with scotchbrite but wonder if I need to do a better job? Might be why I'm eating seals?

I'm using a -10 under chain so I'm a little short. I left the cover on until I figure out a way to measure how far off center I am. I would think being off a hair would eat a seal.

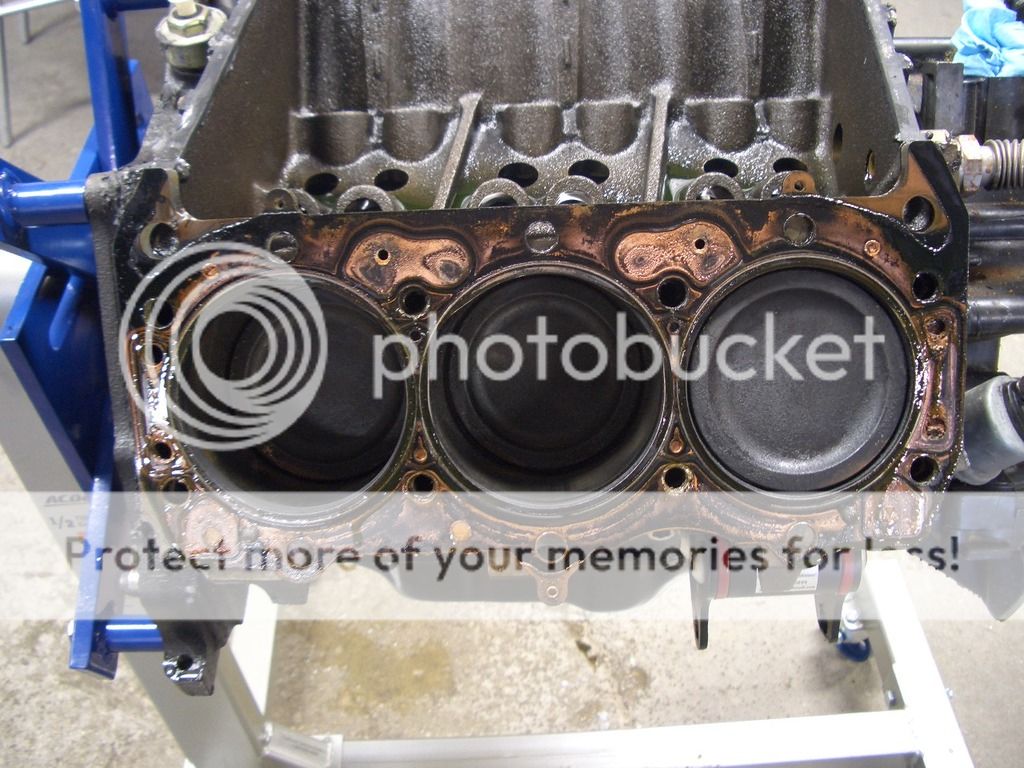

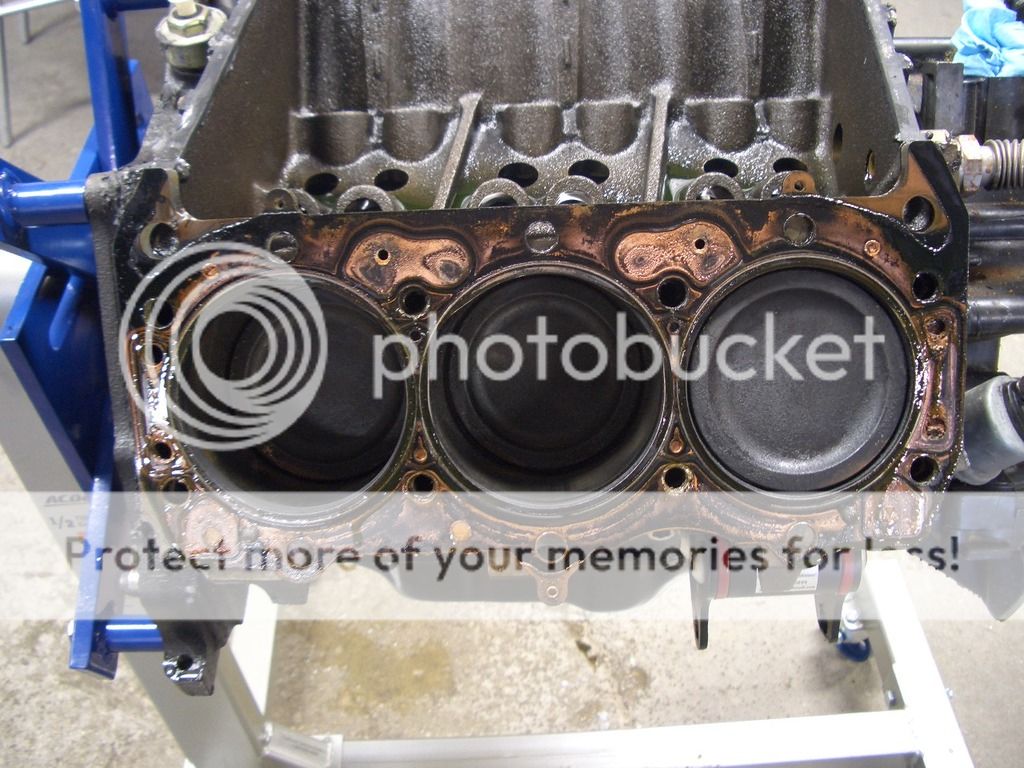

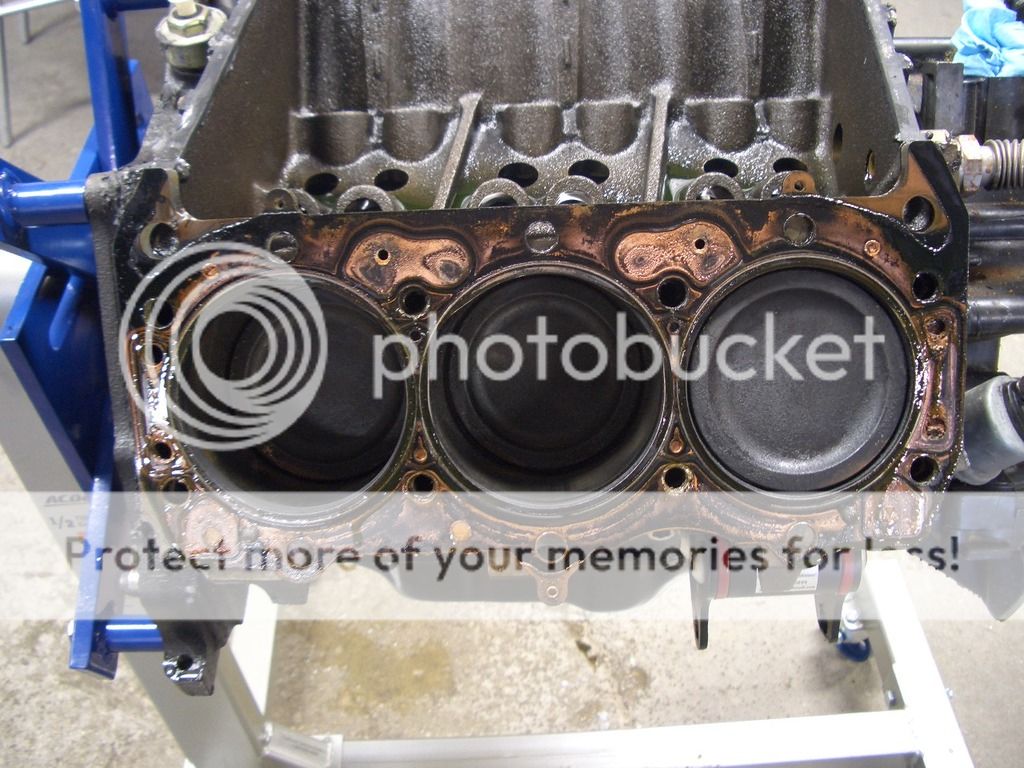

And now for the whole reason I pulled the motor, leaky cometics. Just oil no coolant. They were separated and copper sprayed be fore install.

Every layer is soaked with oil. I'm not real sure where I am going from here. I'm not going to use Cometics again. Not because they're not good because I use them on other motors. It's because I'm unlucky and I'll never get them to seal. I am open to ideas.

I plan to do all the work myself this time so I'll be looking for advice as I go.

I plan to re-use my head bolts

Thinking about the RLC oil pan?

New fuel lines this go around.

Going to get the Turbo saver

That's about it for right now. I'm going to take some measurements again to calculate compression and head gasket thickness. I thought my TA heads were supposed to be 49cc chambers but now their website say's 46?? I'll get them measured to be sure.

So other than cometic what head gaskets are you guy's running with aluminum heads on a 109? What is a good compression ratio do I want to shoot for? I'm 95% street. This motor was targeted at 8.8 and it ran real good at 23 psi. I hated to tear it apart but can't stand the oil leaks.

Brett